Over-fermentation is a sure-fire way to ruin a coffee. The threat of a full sour defect or a ‘stinker’ bean making its way into your cup is enough to put anyone off the idea of stretching out fermentation any longer than necessary. And yet, producers are experimenting with longer and longer fermentation times, and somehow getting away with it.

Colombia-based green buyer, coffee roaster, and BH Coach, Nikolai Fürst helped to develop a coffee this season that has been fermented for a total of 740 hours: a whole month of fermentation. The result tastes ‘almost like a concentrated, intense Kenyan coffee,’ Nikolai says — which, coming from the 2019 German Cup Tasting champion, is high praise indeed.

Omar Arango (left) and Nikolai Fürst (right) at Finca San Luis, Colombia

Omar Arango (left) and Nikolai Fürst (right) at Finca San Luis, Colombia

Making such long fermentations possible requires tight control over the fermentation conditions, to avoid the development of over-fermented, vinegary or alcoholic flavours. Producers have experimented with different ways to slow down fermentation, including excluding oxygen (in the case of carbonic maceration or ‘anaerobic’ fermentations) or cold fermenting.

Cherries fermenting in plastic bags. Plastic bags such as GrainPro are a simple but effective way to exclude oxygen from fermentation.

Nikolai and his producer partner Omar Arango Tinoco at Finca San Luis slowed down fermentation by partially drying the coffee, which reduces microbial activity. They fermented whole cherries in GrainPro bags for 36 hours, then took them out and dried them for four days in the sun, before returning them to GrainPro bags for the final fermentation of 29 days. Drying the cherries in this way reduces the risk of mould, Nikolai says, and allows the coffee to develop some very distinctive flavours.

Whole cherries drying on raised beds. A partial drying step at the beginning of processing allows for very extended fermentation times.

Whole cherries drying on raised beds. A partial drying step at the beginning of processing allows for very extended fermentation times.

This type of coffee needs a few months’ rest before it tastes its best. ‘Extended fermentations are almost always nasty when they’re fresh,’ Nikolai says. ‘The longer and more intense the fermentation, the more time the coffee bean itself needs to stabilise.’

Cherries in the GrainPro bag at the end of their 29-day fermentation step

Cherries in the GrainPro bag at the end of their 29-day fermentation step

‘When this coffee had just finished drying, it was super unstable and high in acidity, tasting like balsamic vinegar, olives, even phenolic — crazy and weird.’ The longer the coffee rested, however, the better it became. ‘When it stabilises, it becomes super juicy and deep, with flavours of red fruits, cacao nibs, very creamy, intense, and rich, with really bright acidity.’

This kind of fermentation offers producers a way to produce distinctive flavours and elevate their cup scores, achieving higher prices for their coffees, without requiring a big investment, Nikolai says. ‘We are always trying to improve coffee quality with processing using easy techniques that don’t need fancy equipment.’

Can You Ferment Five Hundred More?

Extended fermentations are seen as risky, and challenging to replicate. The level of control granted by this process, however, means that Nikolai has been able to repeat this process three times on the same farm, with ‘more or less consistent’ results. While this fermentation experiment was a success, it remains to be seen if the same process can be repeated on other farms, where the local microbes and the conditions during fermentation can be very different. The atmospheric conditions also play a huge part in determining how the fermentation progresses. ‘In Colombia, if you try to do this kind of process during the dry season, and then try to replicate it when it’s raining a lot, that’s impossible.’ Nikolai explains. ‘When it’s raining, the moisture content makes mould explode on the drying beds. But when you have exposure to direct sunlight, then you don’t have problems with mould.’

Nikolai has already experienced first-hand the difficulties of transferring a successful processing method from one farm to another. ‘On one farm, we do a process called “Cinco Dias,” which involves five days’ fermentation submerged underwater before drying. When we tried this fermentation using the same variety on another farm, with the microbes there it’s horrible and tastes really flat,’ he says. On that farm, they instead chose a much more aggressive style of fermentation, deliberately introducing oxygen to encourage microbial growth before moving the coffee into anaerobic conditions.

Most research on fermentation in coffee so far has been focused on removing mucilage as quickly as possible (Lee et al 2015) — so there is very little research on how fermentation affects aroma, and even less on the fermentation of natural coffees. One group of researchers in Brazil have begun studying a style of sealed bag fermentation that they call ‘Self-Induced Anaerobic Fermentation’ or SAIF, which they tried with both pulped and whole cherries. They found that the amount of bacteria present in a fermentation correlated with the acids present (Martinez et al 2021) and that excluding air from a fermentation increased the amount of lactic acid produced (Pereira et al 2022). The coffees they processed this way had more sucrose and less glucose — and sucrose is a more important contributor to the Maillard reactions. As a result, the coffees processed this way were more intense and fruity (Pereira et al 2022).

The increase in lactic acid may be an important part of a successful extended fermentation. Populations of lactic acid bacteria increase during extended fermentations in wet processing (Pothakos et al 2020), and these bacteria and the chemicals they produce tend to help keep unwanted microorganisms out of the tank (Zhang et al 2019).

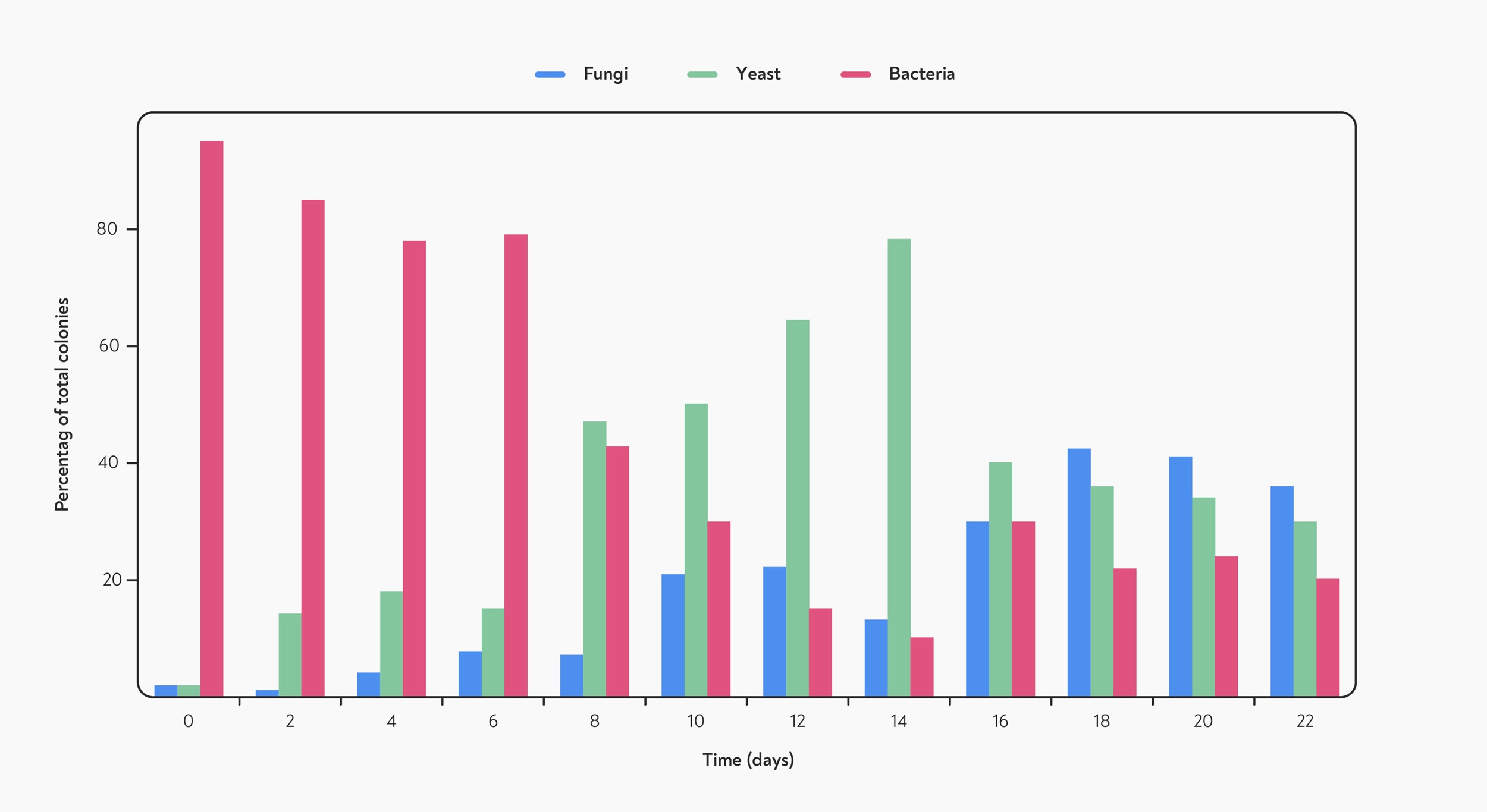

Another clue to the success and replicability of the method comes from research into the fermentation that takes place on the drying beds during standard natural processing (Silva et al 2008). In natural processing, the microbes involved are very different to washed processing, and much more varied. In the early stages of drying, the cherries are mostly colonised by bacteria. However, as the cherries dry out, the bacterial colonies are replaced by single-celled yeasts — considered to be the kind of micro-organisms that are most important in developing coffee flavour during fermentation. The yeasts that grow during this stage tend to prevent the growth of filamentous fungi (the kind of fungi that produce mould). Only towards the end of the drying time do the filamentous fungi emerge, and keeping the coffee dry by proper storage after processing is key to preventing these from growing any further and damaging the coffee.

The proportion of bacteria, single-celled yeast, and filamentous fungi found on coffee cherries during natural processing. Bacterial colonies are most common when the coffee is picked, but yeasts and then filamentous fungi become relatively more common as the coffee dries.

The proportion of bacteria, single-celled yeast, and filamentous fungi found on coffee cherries during natural processing. Bacterial colonies are most common when the coffee is picked, but yeasts and then filamentous fungi become relatively more common as the coffee dries.

It seems likely that by partially drying the coffee before continuing fermentation, this experiment encouraged a very specific mixture of microorganisms to grow. Perhaps the partial drying resulted in more yeasts being present, and reduced the amount of bacteria in the fermentation.

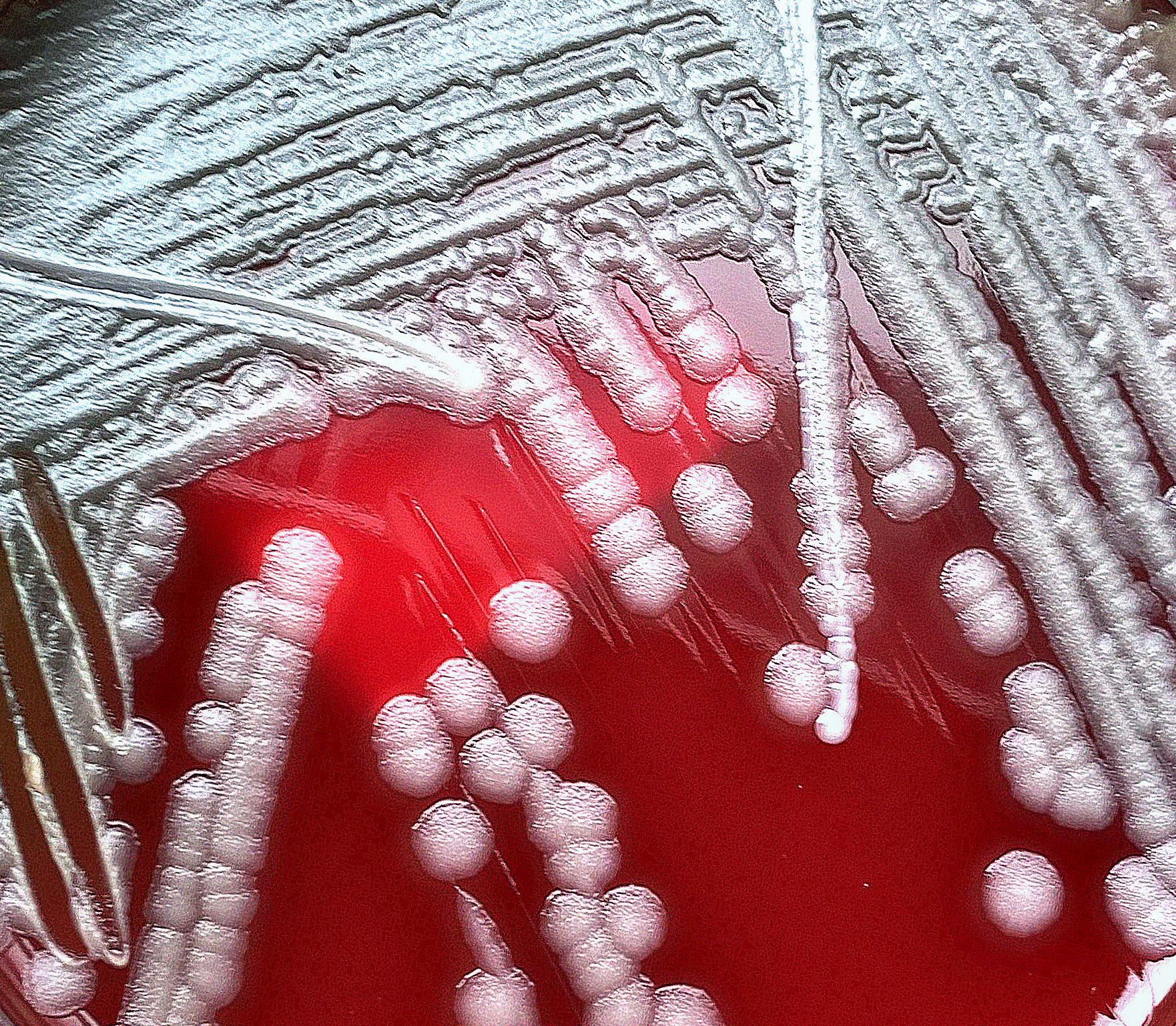

Colonies of Bacillus cereus, a species of bacteria commonly found on coffee during natural processing

Colonies of Bacillus cereus, a species of bacteria commonly found on coffee during natural processing

If that’s the secret to the success of this fermentation, then the key to controlling the fermentation is understanding exactly the moisture content and other conditions that encourage the microbes that perform well in extended fermentations. Without this control, replicating this kind of process with a different coffee will be challenging, but unfortunately scientific research on this subject is only just beginning to catch up with the pioneering work of producers.

Every lot of coffee has a distinct natural microbiome, and a process that works well for one coffee does not always transfer well to another lot. To fully understand what’s happening during extended fermentations will take a lot more research. Until then, extended fermentations may remain risky — but with skill and experience, producers can steer fermentations in unexpected directions. And as this experiment shows, sometimes the results make it worth going the extra mile … or 500.

0 Comments