In our latest poll on the BH Facebook Group, you asked us to check this out: ‘If flow goes in much faster than it comes out, then you have the potential to create a fluidised bed. Where does that leave espresso?’ Here’s what we found out … This question follows on from our posts about agitation in batch brewing and turbulence in espresso. In those posts, we explained why controlled agitation is beneficial in batch brewing, but found out that turbulent flow in espresso could bring over-extracted flavours to an espresso. In some conditions, the agitation from the flow of water in brewed coffee can create a fluidised bed. In this post, we’ll explain what that is, and how to turn it to our advantage in brewing.

What Is a Fluidised Bed?

For coffee geeks, the concept of a fluidised bed is more familiar from roasting coffee rather than in brewing it. In these roasting machines, a stream of hot air is used to lift and separate the coffee beans, allowing them to circulate in the air and thereby roast evenly. The same principles can apply in certain stages of coffee brewing — according to the Coffee Brewing Handbook, in the ideal brewing method, the water flow will ‘lift and separate’ the ground coffee particles (TR Lingle, 1996).

A fluidised bed is made up of a mixture of solid particles and a fluid (a liquid or gas). The motion of the fluid keeps the particles suspended in such a way that the whole mixture behaves in a similar way to a fluid. This means the whole bed can flow, will conform to the shape of the container it’s placed in, and will have a level surface, in just the same way a liquid would. Currents within the bed allow particles to circulate within the mixture, in a similar way that convection allows molecules to circulate in a liquid.

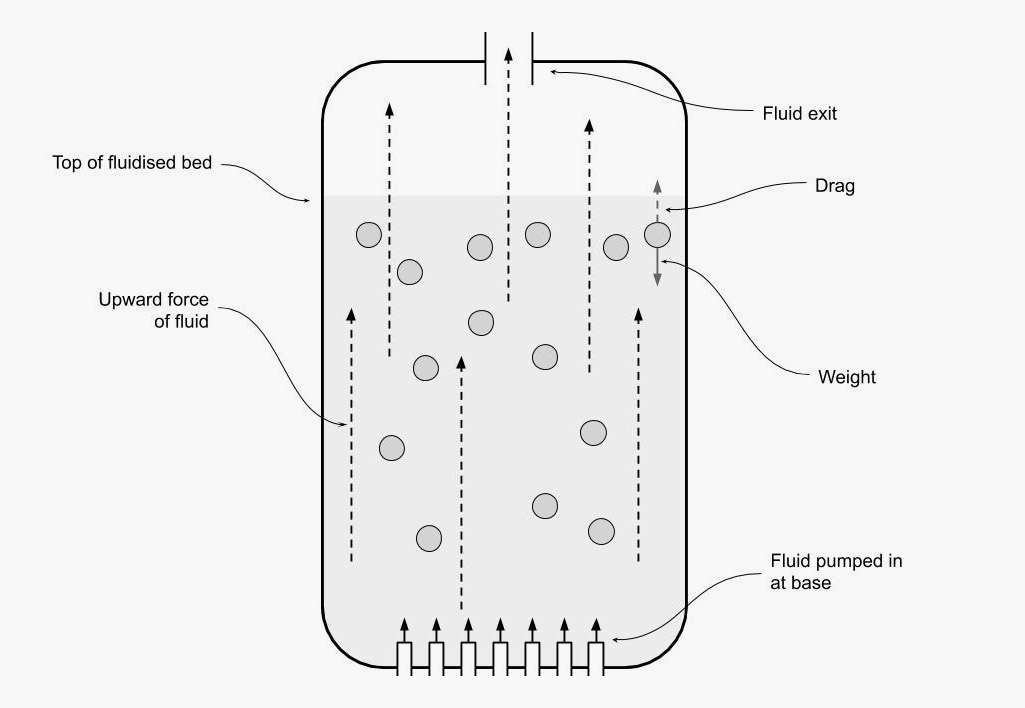

Keeping the particles suspended requires an upwards flow of the fluid in the mixture. The upwards flow creates drag (friction) against the particles, which increases with the speed of the fluid. When the speed of flow is high enough that the drag force becomes equal to the weight of the bed, then the whole bed becomes fluidised (RG Holdich, 2002).

A fluidised bed. The friction of the fluid against the particles creates an upward drag force. When this force equals the downward force from the weight, the bed becomes fluidised.

A fluidised bed. The friction of the fluid against the particles creates an upward drag force. When this force equals the downward force from the weight, the bed becomes fluidised.

How Do We Fluidise the Bed in Brewing?

A fluidised bed requires an upward flow of liquid to lift the particles. Although we pour the water in from the top, if the flow is fast enough it will hit the bottom of the brewer and turn upwards, partially fluidising the bed of coffee. You can see this in action in this small teaser from our Percolation Course:

This video and over 150 other’s just like it is accessible to all our BH Unlimited Customers together with eight challenging online courses and certifications.

During the early part of the brew, vigorous pouring can create enough energy in the flow to partially fluidise the bed of coffee, allowing the particles to be lifted and separated, and ensuring they all come into contact with the brewing water.

As the brew continues, the greater depth of water in the slurry dampens the flow, making it harder for the flow to reach the bottom of the brewer, and thus create the upward currents needed to fluidise the bed.

In batch brewers, the flow of brewing water is spread out over numerous smaller jets, so it’s unlikely that they have enough kinetic energy to fluidise the bed in this way. Some brewer designs however, such as the Bunn Trifecta, inject the brewing water from the base and so can fluidise the bed for part of the brewing time.

What’s the Effect of Fluidising the Bed?

Fluidised beds are used in many industrial processes because the solid and the liquid become very well mixed, allowing efficient transfer of heat or mass between them (RG Holdich, 2002). In brewing, this means coffee solubles can be efficiently transferred to the brewing water.

As you can see in the image above, ground coffee particles are highly porous. The pores form deep channels in the particle, which solubles will need to diffuse out of in order to be extracted into the brew. Diffusion is a slow process, but good mixing, as found in a fluidised bed, will help speed this up by moving solubles away from the top of the pores (Nik Kapur, 2019, personal communication).

In espresso, however, the relatively slow flow of water, and the constrained space in the tightly packed bed means that the bed will not fluidise. However, the nature of espresso extraction, which occurs mainly at the surface of fine particles, means that this is not important in this case.

Pores in roasted coffee are typically 20-50nm across (S Schenker et al, 2008), so the ‘fines’ (sometimes defined as 50nm across or less) that are so important in espresso extraction do not generally include intact pores. This means that the extraction in espresso doesn’t rely on this mixing to allow the brewing water to penetrate these pores.

That said, perhaps combining aspects of Turkish coffee brewing with espresso techniques could provide a consistent way to get full (25%+) extractions in the future, by fully extracting the larger particles that espresso misses as well as the fines. We imagine a two stage brewing method that uses fluidisation or agitation in the first step to allow diffusion from deep pores in the larger particles, followed by a high pressure draw down to get the strength and mouthfeel of espresso. If we work out how to do this, we’ll let you know!

Fluidising the bed has one more effect which could play a part coffee brewing. Particles of different sizes within a fluidised bed tend to separate out by size: larger particles sink, and the smallest particles collect at the top (Z Zhang and JM Beeckmans, 1990). This is opposite to the ‘Brazil nut effect’ described in our post on fines migration, and could explain why a spent coffee bed sometimes has a visible, muddy-looking layer of fine particles on the top. We would speculate that where it occurs, if the different sized particles are not then stirred back together, this separation of particles could make for less even brewing.

RG Holdich, 2002. Chapter 7: Fluidisation. In: Fundamentals of Particle Technology, pp 68-76. ISBN 0-9543881-0-0. Available online at http://www.particles.org.uk/particle_technology_book/

TR Lingle, 1996. The Coffee Brewing Handbook, second edition, pp 29-33

S Schenker, S Handschin, B Frey, R Perren, and F Escher, 2008. Pore Structure of Coffee Beans Affected by Roasting Conditions. Journal of Food Science. 65. 452 – 457. doi:10.1111/j.1365-2621.2000.tb16026.x

Z Zhang and JM Beeckmans, 1990. Segregation in a stirred fluidised bed. The Canadian Journal of Chemical Engineering, 68(6), 932–937. doi:10.1002/cjce.5450680606

0 Comments