Why hasn’t anyone made a small affordable roller mill yet? How hard can it be?

Industrial grinders, of the sort used to produce espresso pods or supermarket packs of pre-ground coffee, are more or less exclusively roller mills. The most sophisticated of these grinders can grind coffee without significantly heating the grounds, and in the process produce very narrow particle size distributions with minimal fines. This makes roller mills ideal for grinding coffee, except for the inconvenient fact that they are very expensive, and too large and complex to be used in cafes or small roasteries.

What Are Roller Mills?

A roller mill grinds coffee by passing it between a pair of grooved steel cylinders that rotate against each other, forcing coffee through the gap in between. They can grind huge volumes of coffee, typically measured in kg/hr, which makes them essential for industrial applications.

Roller mills can also produce relatively spherical particles of coffee, with a very defined and narrow particle size distribution, which is part of the reason that espresso pods can produce such high extractions in a short time (J. Hoffmann, 2015). Multi-stage roller mills can also be configured to produce specific multi-modal particle size distributions, for example if a bimodal distribution is preferred for espresso.

Roller mills used in coffee always have at least 2 pairs of rolls: the first pair are the pre-breakers, which roughly crush the beans into smaller pieces of about 1mm in size. The second pair then applies shear stress to ‘cut’ these pieces to the desired size (M. Petracco, 2005). The most uniform grind size is achieved by using multiple grinding stages that progressively reduce particle size (R.J. Clarke, 1987).

The grinding rolls have grooves on their surfaces called corrugations, designed to hold and cut the beans in specific ways. The rolls must be cast and cut with great precision, which means that making the rolls themselves is expensive.

A special technique called centrifugal die casting has to be used, explains Dr Stefan Schenker, head of the Coffee Business Unit at Bühler: molten metal is poured into a mould, which is then spun at high speeds to force the metal into the edges of the mould and eliminate any microscopic bubbles or gaps.

Once the roll is cast, the corrugations in the rolls then need to be cut, typically at a slight angle to the axis so they twist around the roll, in order to avoid engaging the entire length of a corrugation at once. Because of the complex manufacturing processes involved, the cost of replacement rolls runs into the thousands of dollars, if not tens of thousands, Schenker says.

Crushing and Cutting

Achieving a narrow particle size distribution and more spherical particles requires cutting forces (shear) rather than crushing the bean (compression). If the rolls move at the same speed, the particles are crushed as they are drawn into the narrowing gap between the rollers, creating a wide range of particle sizes as the beans shatter.

To produce the cutting motion that produces a more defined particle size, the rolls have to move against each other at different speeds. When this happens, the surfaces of the rolls move relative to each other, which generates shear forces on the coffee particles. Roller mills used for coffee typically have slanted, u-shaped corrugations that produce very sharp edges — so this type of shear forces created are usually described as ‘cutting’, and work in a similar way to the cutting motion of a pair of scissors, as opposed to the pure ‘shear’ forces that would be created by blunt or smooth rolls.

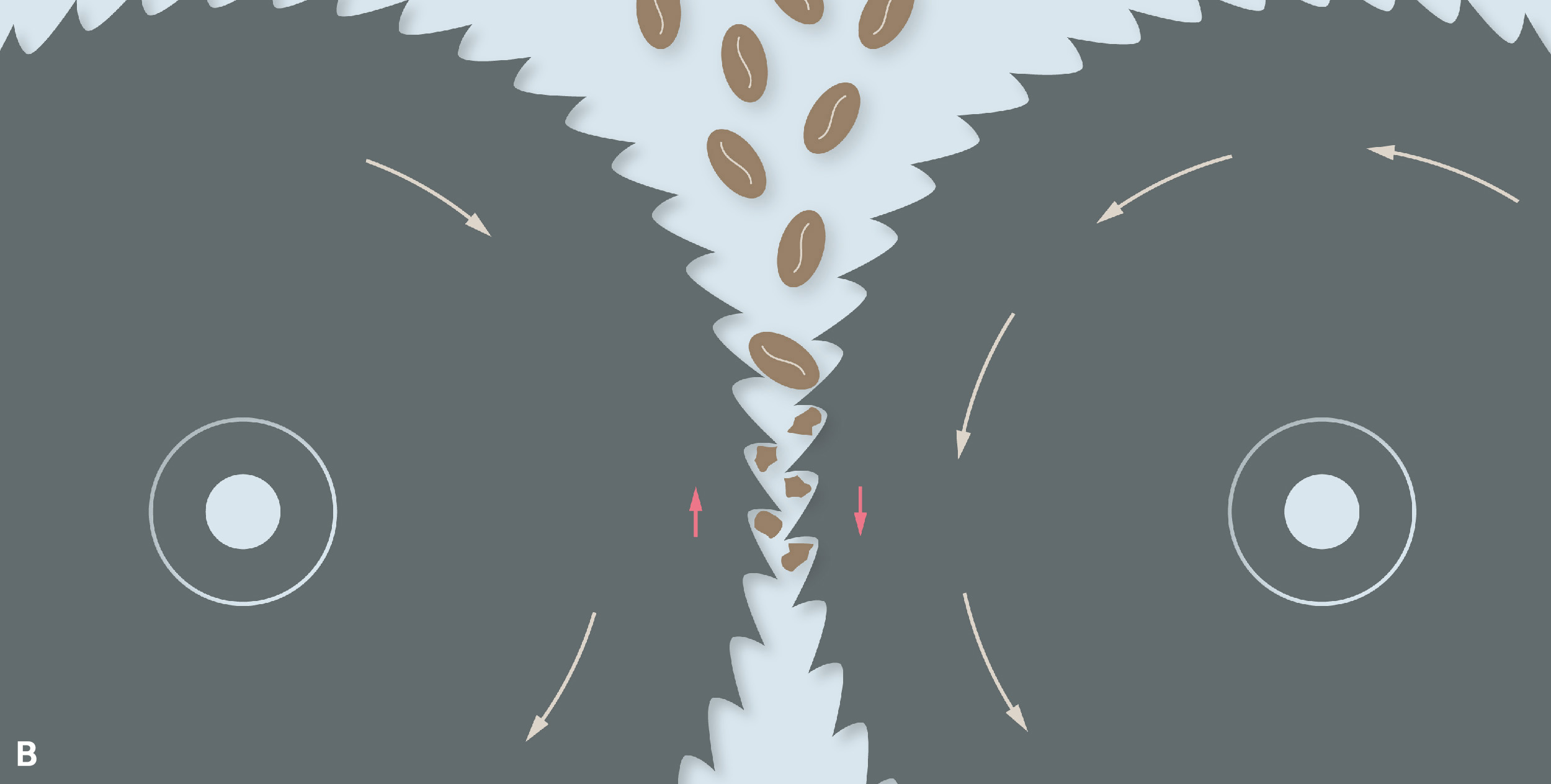

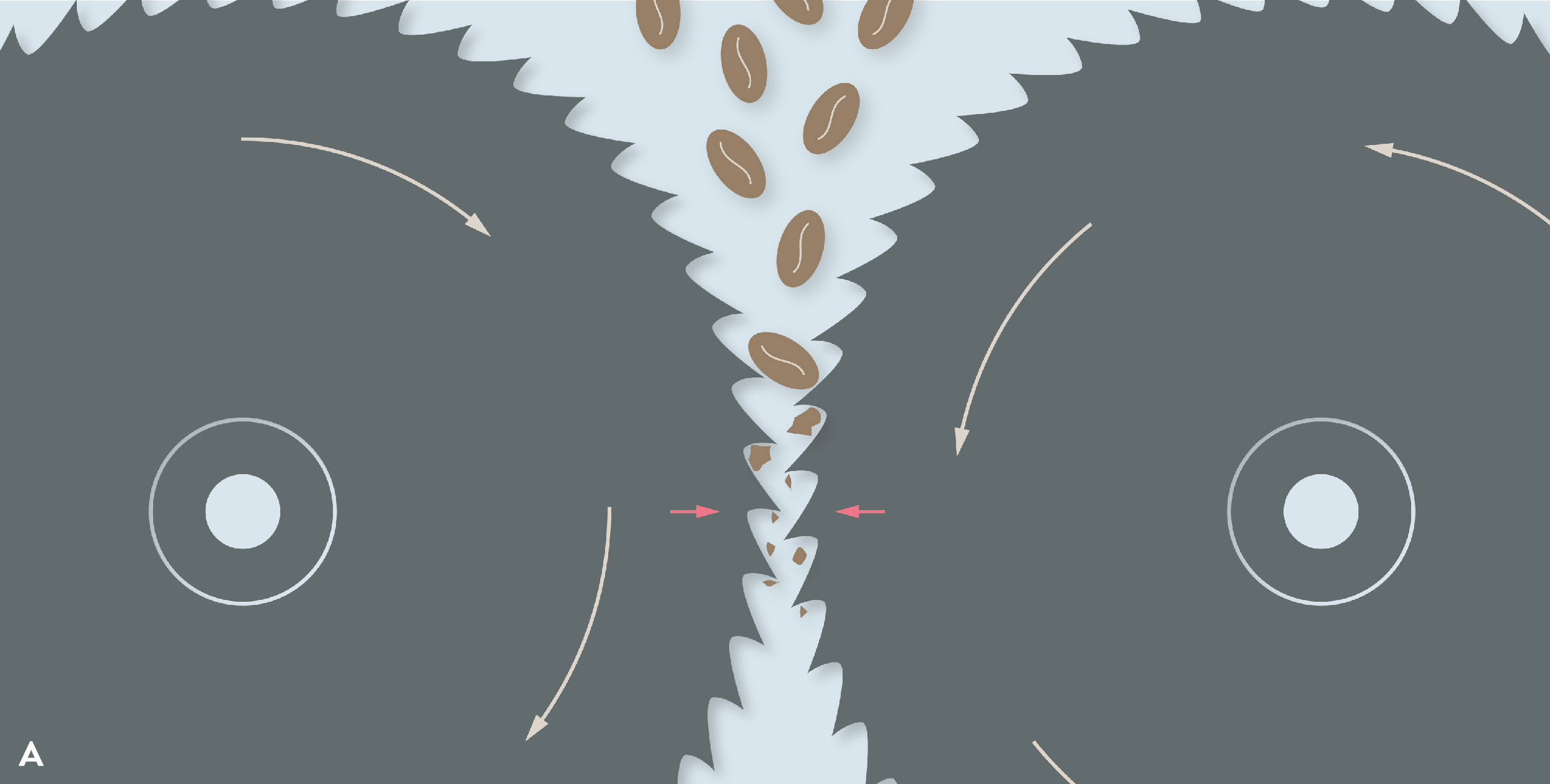

Crushing and cutting in roller mills. When the rolls move at the same speed (a), the beans are crushed by compression forces (shown by red arrows) as they are forced through the gap between the rolls. When the rolls move at different speeds (b), the particles are ‘cut’ by shear forces in opposing directions (shown by red arrows). Although both rolls are turning towards the centre, the difference in speed between them means that the forces on the particles act in opposite directions, creating the shear force needed to create the cutting action of the rollers.

Crushing and cutting in roller mills. When the rolls move at the same speed (a), the beans are crushed by compression forces (shown by red arrows) as they are forced through the gap between the rolls. When the rolls move at different speeds (b), the particles are ‘cut’ by shear forces in opposing directions (shown by red arrows). Although both rolls are turning towards the centre, the difference in speed between them means that the forces on the particles act in opposite directions, creating the shear force needed to create the cutting action of the rollers.

Controlling the relative speed of each of the rolls individually is technically challenging, and is a major contributor to the complexity and size of roller mills. “Modern 3-stage grinders are expensive because the world of espresso pods has demanded a technological leap,” explains a grinder technician at a major roasting company. “The grind quality depends on modulating the speed of the rollers, which requires new technology such as inverters and new motors, and the rolls require new materials and high-precision construction.”

Adjusting the Grind Size

Because roller mills grind in multiple stages, correctly adjusting the grind size means not just adjusting the gap between the last pair of rolls, but adjusting the gap between each pair. Adjusting the gap size is much more complex than adjusting the gap between concentric burrs, and requires complex and expensive mechanisms to control it (M. Petracco, 2005).

Maintaining alignment is a particular problem. In burr grinders, where the burrs are small and there are only two axes of alignment, alignment is relatively simple and isn’t affected by grind size changes. In a pair of rollers, both ends have to be moved by exactly the same amount to maintain alignment. The distance between the points of alignment, and the fact that each end needs to be perfectly aligned in three dimensions, makes alignment in roller mills much more complicated than in burr grinders, and roll alignment tools are a whole industry in themselves.

To maintain a narrow particle size distribution, multiple other factors also need to be adjusted, including the roll speeds, the speed difference between them, the feed rate of coffee beans from the hopper, the number of grinding stages used and even the type of rolls used. The best configuration for a given grind size must be found by trial and error (M. von Blittersdorff & C. Klatt, 2017). Adjusting the grind is thus often not a simple matter of adjusting the gap between rolls, but a time consuming process that requires a skilled operator, and may involve switching out rolls as well as adjusting many other settings.

Roll Size

The first step in producing a compact roller mill would be to reduce the size of the rolls. However, there are two major constraints on the size of the roll:

Firstly, the diameter is constrained, because of the way the coffee beans enter the roll. “You need a certain angle [between the rolls] called the feed angle, that limits how small the roll can be,” Schenker says. This means the smallest effective rolls for coffee are 200mm in diameter, he says, which puts a hard limit on how well these grinders can scale down.

The feed angle, also called the nip angle, is the angle between the rolls at the point they contact the bean (shown in red). Smaller rolls (b) have a larger feed angle, which affects their ability to draw the coffee into the gap between the rolls.

The feed angle, also called the nip angle, is the angle between the rolls at the point they contact the bean (shown in red). Smaller rolls (b) have a larger feed angle, which affects their ability to draw the coffee into the gap between the rolls.

The second limitation is related to cooling systems. Because the diameter of rolls has to be much bigger than the thickness of burrs, they expand much more when subjected to heat than burrs do. At espresso grinds, the gap between rolls is only a few microns, so even a slight expansion in the steel can cause problems, Schenker explains.

Roller mills are typically cooled with water running through the core of the roll. This type of cooling mechanism is only possible with a certain length of roll, which limits how small they can go, he says. “If you really wanted a consistent result, cooling would be necessary.”

How Small Can Roller Mills Be?

The size of the mechanisms needed to set and adjust the grinding gap and speed, and the complexity involved in getting the right settings, means that even the smallest roller mills aren’t practical in cafe settings.

However, there are some examples of smaller roller mills out there. Roller mills are commonly used to crush grain for brewing, for example, and for this purpose it’s even possible to buy small hand cranked mills. However, the particular requirements of coffee grinding mean that this type of mill won’t work well for coffee. “Coffee is one of the most challenging grinding processes you can find in the food industry,” Schenker says. “Particle size distribution is so important, and coffee has tricky properties: it sticks everywhere because of oils and static.”

Because the particle size distribution isn’t as important in beer brewing, these mills can be made with much simpler mechanisms that simply crush the grains — however, this makes them pointless for use in coffee, where an equivalent burr grinder can produce a much better grind quality.

“Bühler are working right now on a smaller scale roller mill called the Grindprecise, designed for high precision but lower throughput, for example for filling capsule systems,” Schenker says. Even this small scale mill, however, will be designed for volumes of around 50-200kg per hour. The smallest commercial roller mill available for coffee has two pairs of rolls rather than the usual three, and uses unusually small 140mm rolls, but the main body of it is still over a metre tall and half a metre wide, even without including the stand and hopper.

There are also roller mills designed for lab use, which have the same mechanisms as their full size cousins, and use rolls of the same diameter but of much smaller length. These can be used to test different configurations to achieve the ideal particle size distribution. However, because of the complex mechanisms required, these are still very large pieces of equipment compared to disc grinders.

“Roller mills need three pairs of rolls for fine grinds, multiple strong motors, scrapers to keep the rolls clear, and a feeding mechanism to make sure the beans are fed evenly to the rollers,” Schenker explains. “In a disc grinder, all this work is done by a single stage.”

The Future

Given not only the limitations on size and cost, but also the complex adjustments involved in setting a grind size, roller mills remain impractical for small scale use. However this doesn’t mean it would be impossible to build a smaller roller mill in the future, Schenker says. “If you asked me if it’s possible I would say theoretically, yes. It would still be bulky though, and expensive, but at the same time you would have to compromise on things.”

Manufacturing precision is improving all the time, and novel coatings and materials such as ceramics offer increased hardness and rigidity. The roll gap and alignment in modern roller mills can be computer controlled, allowing minor grind size adjustments to be made during operation rather than with the grinder shut down (D Ephraim, 2006), which is an important step towards making them easier to use.

It’s worth noting that the focus on grind quality is a relatively recent phenomenon, Schenker points out. “More and more manufacturers have become aware that particle size distribution really matters — with the appearance of capsule systems this have changed dramatically,” he says. “Over the last 5-7 years, this has become more important, but it really depends on the application — for retail packs of filter coffee, nobody really cares [about particle size distribution].” Even some large manufacturers have been slow to switch to roller mills, he says. “I’ve even seen large factories using 30 or so disc grinders instead of a roller mill.”

Perhaps this means that as roller mills become more widely adopted, the cost could come down somewhat, even if there are limitations on the size. However, the grind quality available from burr grinders is also improving, for example with new materials and burr designs, or better control over grinding speed and temperature, which might reduce the gap that currently exists between burr grinders and roller mills.

0 Comments