Making good espresso requires machines that are ‘stable’ — that is, they maintain set parameters, such as temperature or pressure, no matter what you throw at them. Controlling these variables is key to making consistent espresso.

In order to find out more about how such machines work, in this lesson we talk to two espresso machine designers who have used nontraditional methods. John Buckman will be well-known to most readers as the founder of Decent Espresso, a machine that has helped change the way we think about modern espresso techniques. Ben Katz is a robotics engineer at Boston Dynamics who in his spare time is building the unusual skeletal espresso machine first featured in Lesson 4.05. As he puts it,

‘[I am] approaching the espresso machine design problem the same way as I would designing a robot.’

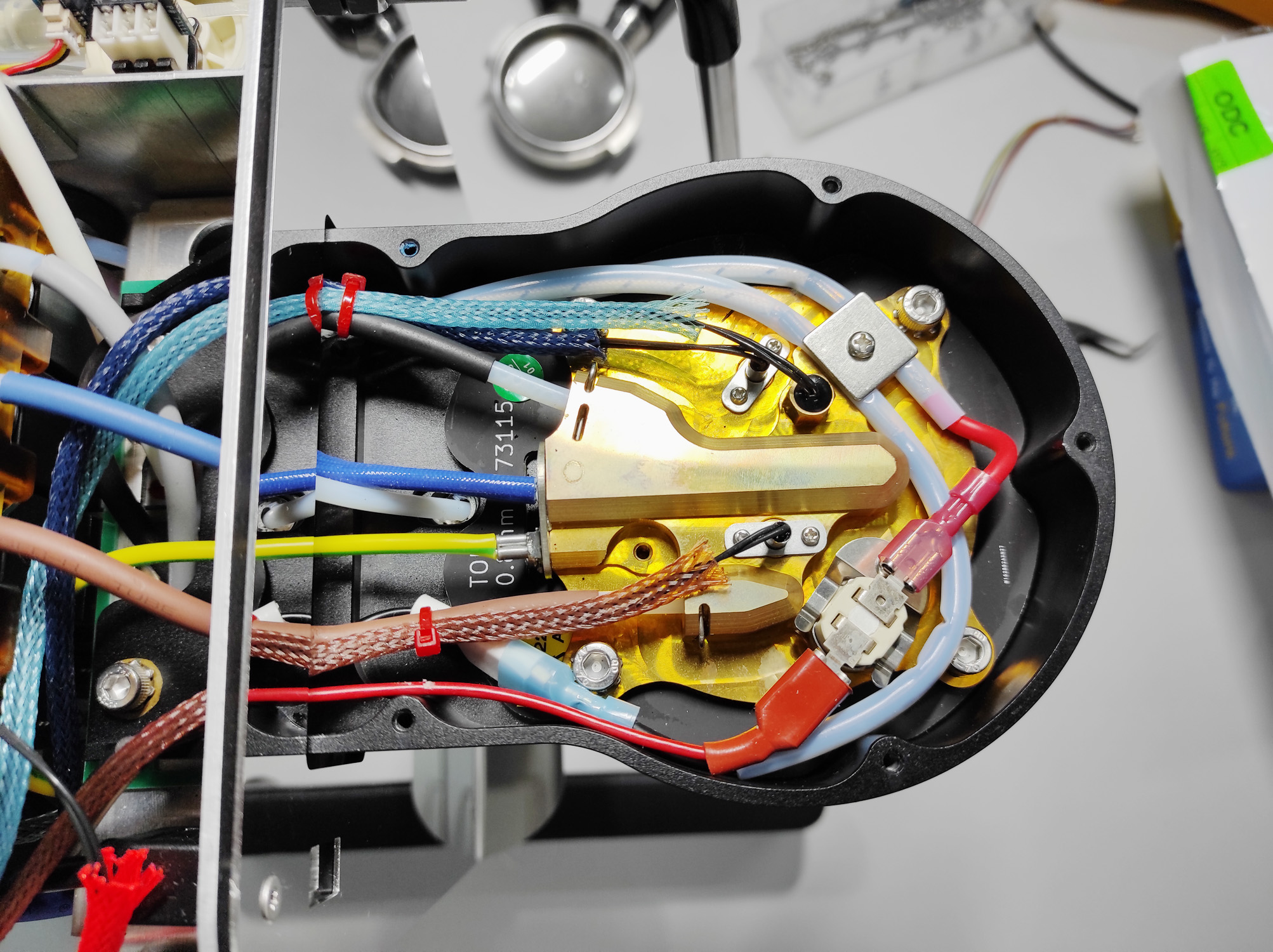

The group heads of a Decent Espresso DE1 (left) and Ben Katz’s home-built machine (right). Both use software modelling to replace functions carried out by hardware in traditional machines

Similarly, a typical rotary pump used in espresso machines can deliver up to 150 litres of water per hour, which is equivalent to 1,250 mL per 30 seconds. The maximum flow rate required at the group head (aka water debit) is 200–280 mL per 30 seconds, less than a quarter of what the pump is capable of.

Big machines and powerful hardware, however, are not the only ways to achieve thermal stability. As we discussed in Lesson 4.05, sophisticated software can allow modern machines to be more stable and controllable than traditional designs — without relying on large, expensive hardware. The most striking examples of this might be the machines built by Decent Espresso.

Stabilising Temperature

Decent Espresso uses a unique method to achieve temperature stability at the group head. Instead of relying on the mass of the group head to heat or stabilise the temperature of the water,