As you may remember from Chapter 1, we have invited Bruce Whetton to be our consulting electrician for this course. Bruce is well qualified for this role because as well as being a certified electrical engineer, he is also a barista trainer and has owned and operated several cafés. Below, Bruce offers an expert description of the technology behind Luigi Bezzera’s Gigante machine. He also explains how modern thermostats control the water temperature in an espresso machine.

Likely because Luigi Bezzera was a mechanic and not an engineer, he used a pressurestat (a switch that turns the heating element on and off) in his espresso machine that was similar to one used in a car. It functioned by means of a wax pellet that melted within a sealed chamber and expanded at a set temperature, which in turn cracked open a spring-loaded valve to release the pressure. At this point the heat source, a gas flame, had to be manually turned off or at least turned down. Because these very early espresso machines were heated by gas, simply breaking the electrical circuit was not an option.

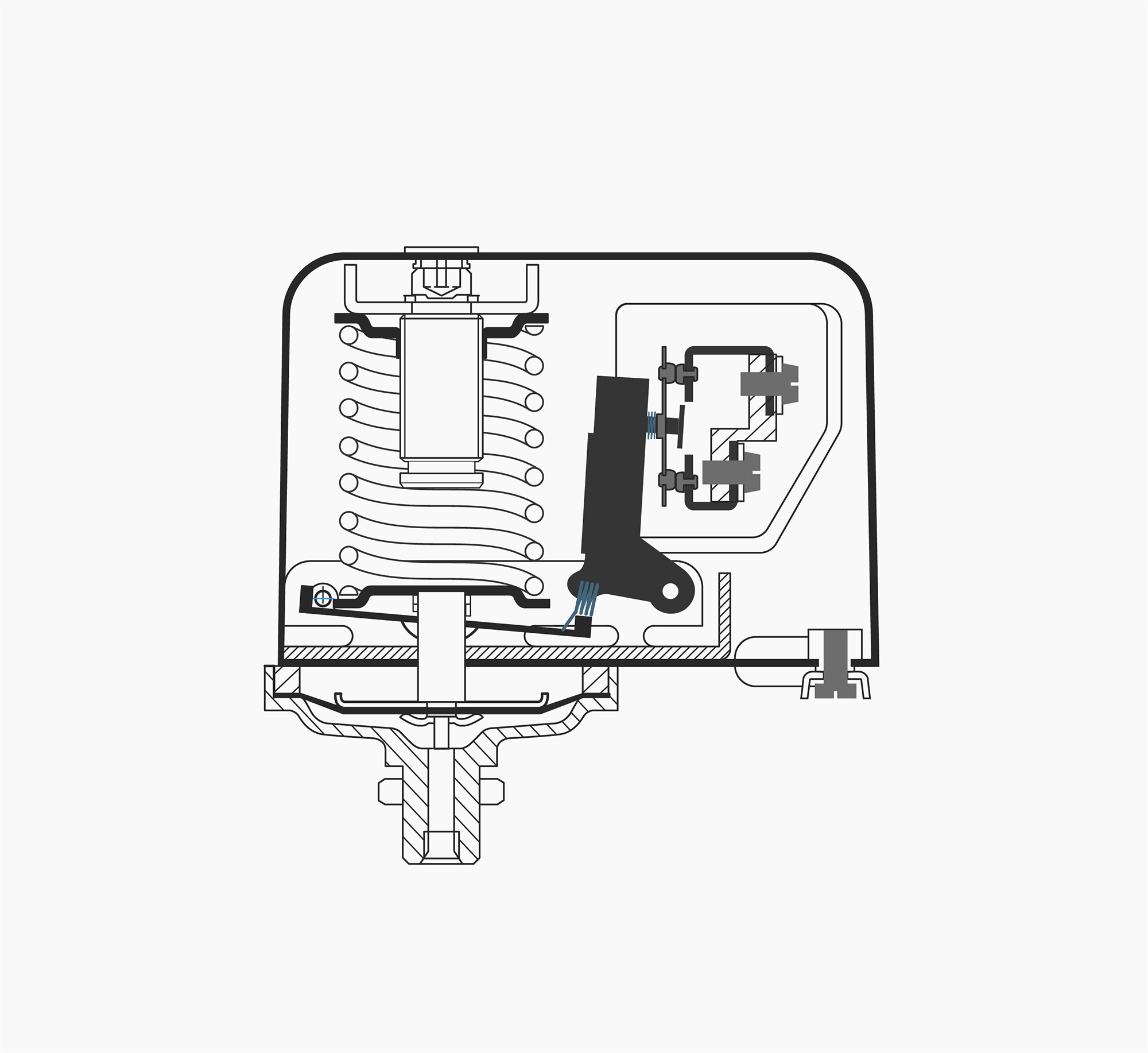

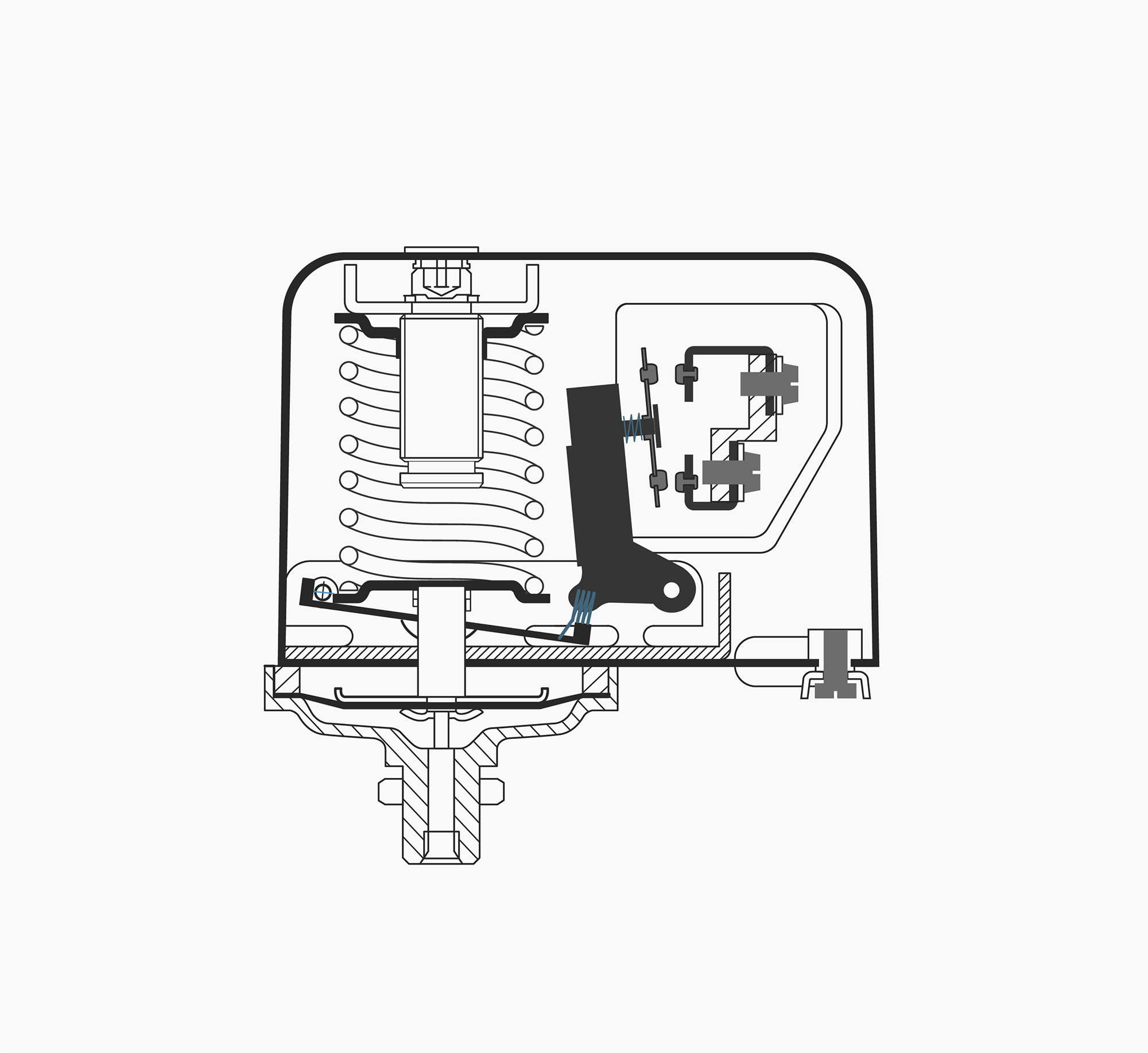

Left image shows a pressurestat capable of switching a 30 amp load, often seen in commercial coffee machines. Right image shows a pressurestat capable of switching a 16 amp load, often used in domestic espresso machines.

Functional diagram of a commercial pressurestat. On the left the switch is closed (ON) and on the right the switch is open (OFF).

When electricity was first used in espresso machines, pressurestats were activated by the pressure created by the water heating up and producing steam. The steam pushed a diaphragm against a tensile spring; this spring’s tension was calibrated to a preset pressure. When the desired pressure was achieved, the pressurestat opened an electrical circuit, breaking the circuit supplying energy to the heating elements and allowing the water to cool.