A copper boiler with brass end plates.

Modern espresso machine boilers are quite basic and usually manufactured from brass, copper, or stainless steel. Copper has been used in boilers and cookware over the years because it’s a good conductor. This means a copper boiler or pan is much more effective than a steel one at transmitting heat from the flame underneath to the water inside it. Copper has a thermal conductivity of over 400 W/mK, compared with stainless steel’s 14 W/mK. Because brass contains copper, it retains some of copper’s properties. Brass has a low melting point, which makes it easy to cast, is relatively soft, and has low friction, which makes it easy to machine. This makes it an ideal material for threaded parts or more intricate components, especially where moving parts are involved. Machines with steel boilers and groups might use brass for safety valves or for compression nuts to connect pipework.

A machine with stainless steel boilers, copper pipework, and brass fittings

A machine with stainless steel boilers, copper pipework, and brass fittings

Like copper, brass’s conductivity is also much higher than that of stainless steel. The conductivity varies, depending on how much copper the brass contains, but it usually measures in at around 111 W/mK. Brass has the advantage of being much harder and stronger than copper. When a boiler is made of copper, its end plates are usually made from brass because brass has a better combination of strength, thermal conductivity, and workability.

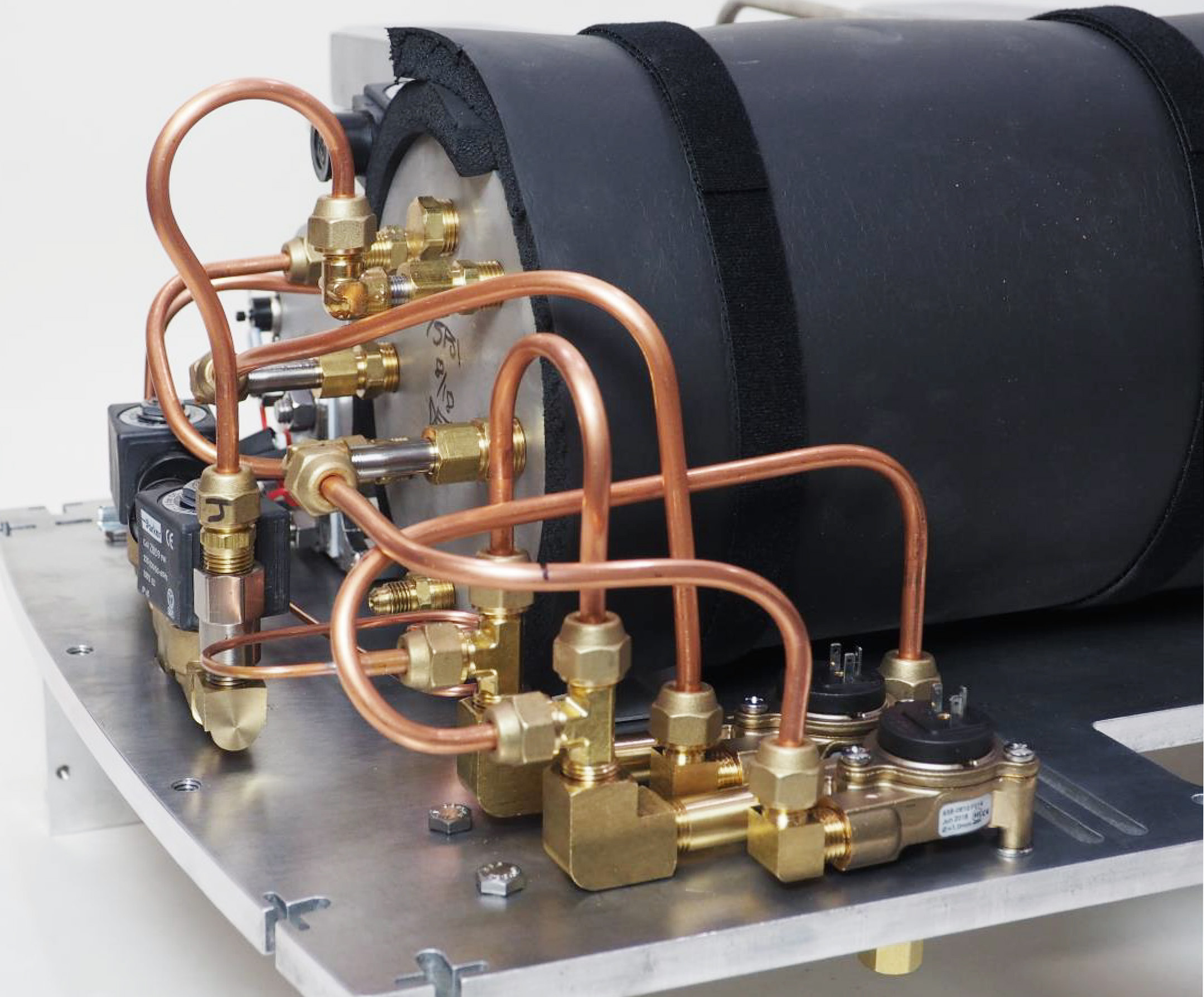

A copper boiler from the famous Faema E61 machine from 1961, which has brass housings brazed onto the copper boiler. (Note: Brazing is very similar to soldering, where a metal alloy is melted into the gap between two adjoining metals that are heated to a high temperature).

A copper boiler from the famous Faema E61 machine from 1961, which has brass housings brazed onto the copper boiler. (Note: Brazing is very similar to soldering, where a metal alloy is melted into the gap between two adjoining metals that are heated to a high temperature).

Most espresso machines — especially older designs — rely on transferring heat from the boiler up to the group head. Water itself is a poor conductor of heat,