Most commercial espresso machines use a rotary pump to pressurise the brewing water. In most cases, this pump is located inside the machine, in which case you’ll need to remove a panel in order to access it. In La Marzoccos and some other machines, the pump is external, so you’ll find it connected to the plumbing underneath the machine.

Video: A technician adjusts the pump pressure in a traditional espresso machine.

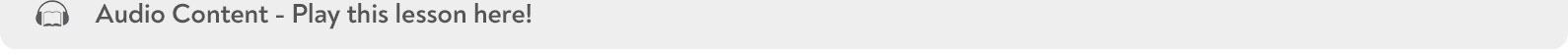

The pump consists of two parts: a large motor and a smaller brass pump head, which is attached to the motor with a clip or bolts. The pressure at the pump is controlled by a screw on the side of the pump head. This screw may have a lock nut on it that must be loosened before the screw can be turned. Turning the screw clockwise increases the pressure, and turning it anticlockwise reduces the pressure.

Espresso machine pump head and motor (a: motor, b: vane pump, c: bypass adjustment).

Espresso machine pump head and motor (a: motor, b: vane pump, c: bypass adjustment).

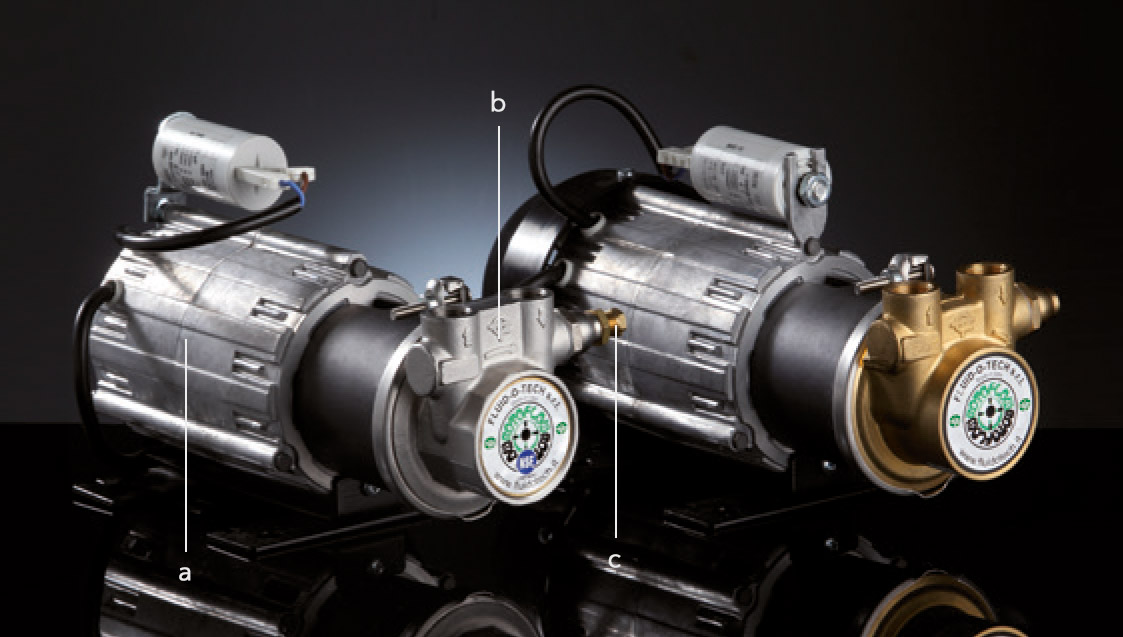

Here’s how it works: the rotating vanes in the pump create the pressure by pushing the water towards the exit. The pump generates more pressure than is needed, so some of the pressure can be released back to the inlet via the bypass valve. Turning the adjustment screw anticlockwise opens this valve up, releasing more of the excess pressure, so the output pressure goes down. Turning the adjustment screw clockwise closes the bypass valve, so more of the pressure is directed towards the machine.

An espresso machine pump head. One side connects to the water supply (a). Rotating vanes in the pump (b) pressurise the water leaving the pump (c). The bypass valve (d) releases excess pressure and is controlled by the adjustment screw (e).

An espresso machine pump head. One side connects to the water supply (a). Rotating vanes in the pump (b) pressurise the water leaving the pump (c). The bypass valve (d) releases excess pressure and is controlled by the adjustment screw (e).

In machines with a vibration pump (mostly, machines intended for home use), this pressure is also controlled by an overpressure valve (OPV). The OPV releases excess pressure back to the water supply — however,