Momentum is a term widely used in coffee roasting to describe the way changes in bean temperature and rate of rise lag behind gas and airflow changes in the roaster. Momentum is often linked to the bean-temperature rate of rise (RoR). For example, it’s common to hear roasters talk about entering first crack with enough momentum to finish the roast — meaning, with a high enough RoR.

A high rate of rise at the beginning of first crack is sometimes said to give the roast ‘momentum’, but it is more accurate to think of it in terms of the amount of heat energy stored in the roaster.

A high rate of rise at the beginning of first crack is sometimes said to give the roast ‘momentum’, but it is more accurate to think of it in terms of the amount of heat energy stored in the roaster.

It’s important to understand that this apparent momentum is illusory. The RoR depends on the temperature difference between the bean and its environment. If you remove that temperature difference, the bean temperature will immediately stop increasing — in other words, there is no intrinsic ‘momentum’ to the rate of rise.

However, if you turn the gas off during the roast, the roaster itself and the roasting gases still contain a lot of heat energy. As long as the roasting surfaces and the gas inside the roaster remain hotter than the beans, they will continue to transfer heat to the bean. This stored energy creates the illusion of momentum in the bean temperature, because it will continue to rise, for a time, even with the gas switched off.

A high RoR results when the temperatures of the roaster and roasting gases are much higher than that of the beans. When the RoR is high, therefore, the roaster and roasting gases have more energy available to transfer to the beans. This is why a roast with a higher RoR appears to have more ‘momentum’ — the hot roaster and roasting gases contain more energy.

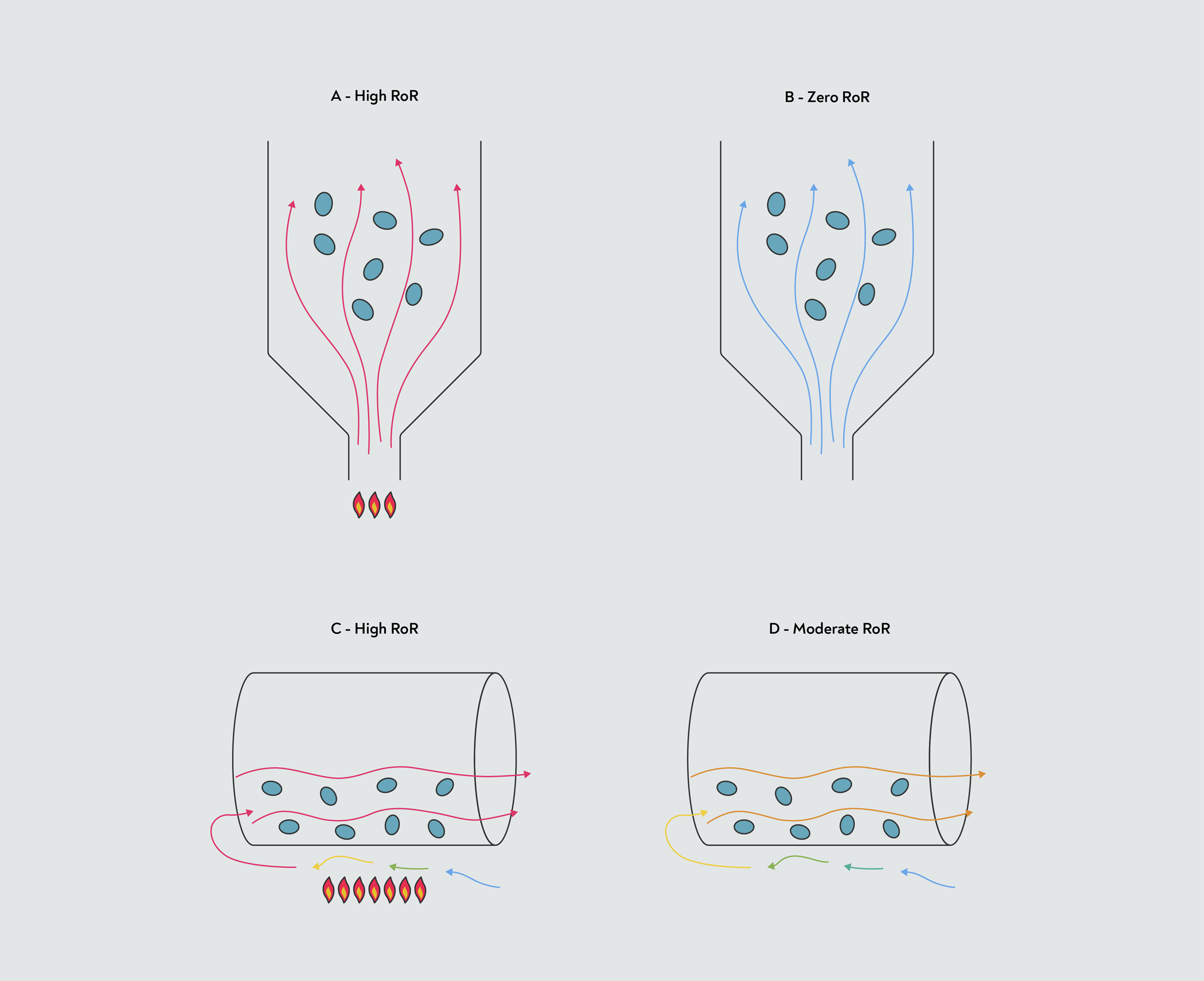

‘Momentum’ in fluid-bed and drum roasters. In the fluid-bed roaster (a), virtually all the heat transfers to the beans via hot air. The large temperature difference and efficient heat transfer lead to a high rate of rise (RoR).

‘Momentum’ in fluid-bed and drum roasters. In the fluid-bed roaster (a), virtually all the heat transfers to the beans via hot air. The large temperature difference and efficient heat transfer lead to a high rate of rise (RoR).