While specialty coffee roasting continues to be dominated by the classic drum roaster, industrial-scale roasters have experimented with different kinds of machines that are designed for consistency and fast roasting at high production volumes.

Continuous Roasters

In a continuous roaster, a conveyor moves coffee through the body of the machine. Instead of being roasted in batches, green coffee continually enters at one end and roasted coffee exits at the other.

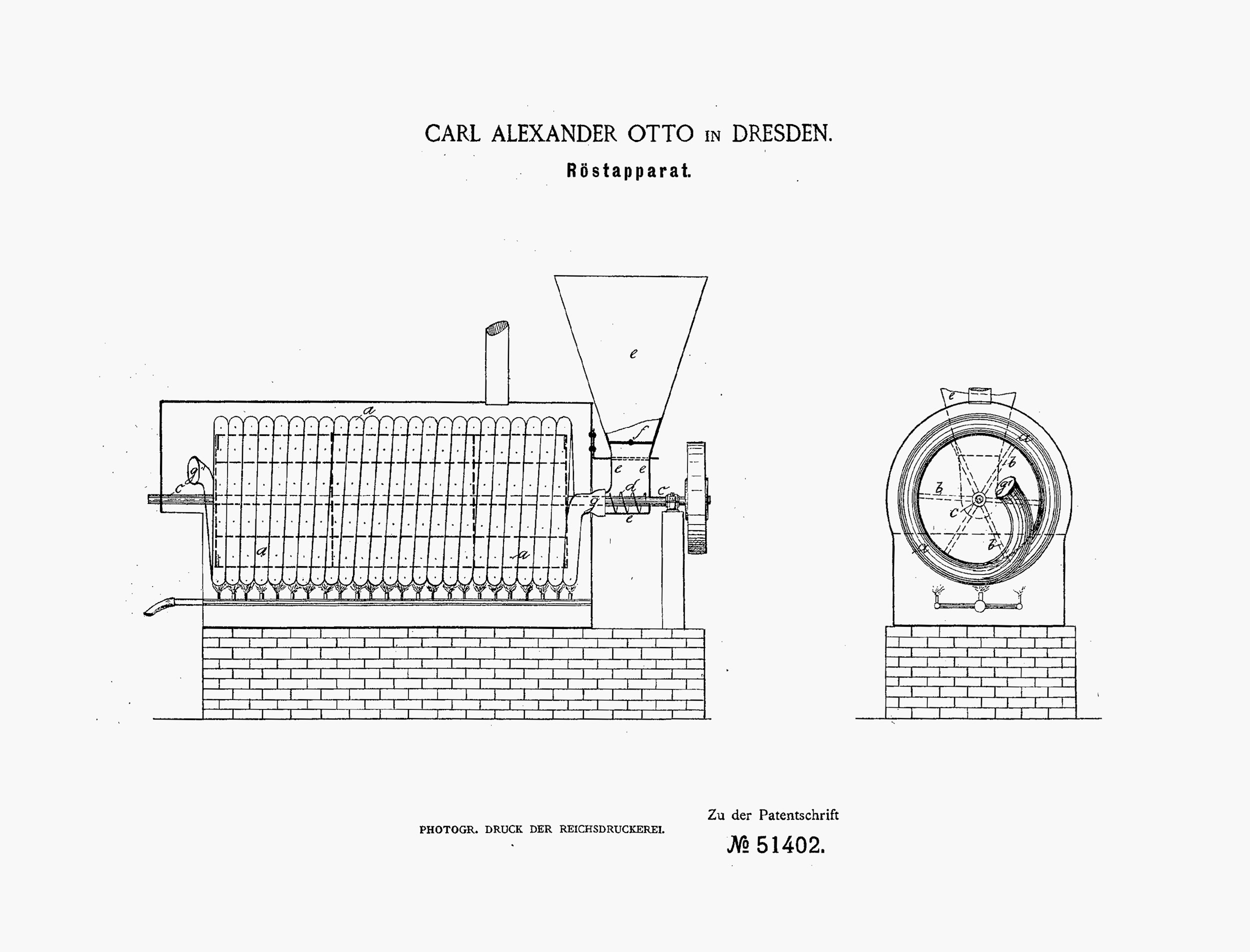

Carl Alexander Otto was the first to patent a design for a continuous roaster, in 1889. Otto’s design used a rotating spiral tube to convey coffee beans through a single heated chamber (Otto 1889).

Detail from Carl Alexander Otto’s 1889 patent for a continuous roaster

Detail from Carl Alexander Otto’s 1889 patent for a continuous roaster

The first commercially successful designs arrived in the 1940s, beginning with the Burns Thermalo continuous roaster (Clarke 1987). This roaster used a spiral within an elongated, perforated drum to convey beans through the machine in as little as 5 minutes. Hot air pumped in at one end of the drum provided the heat for roasting, while at the other end, cold air passed through the drum to cool the beans before discharging them.

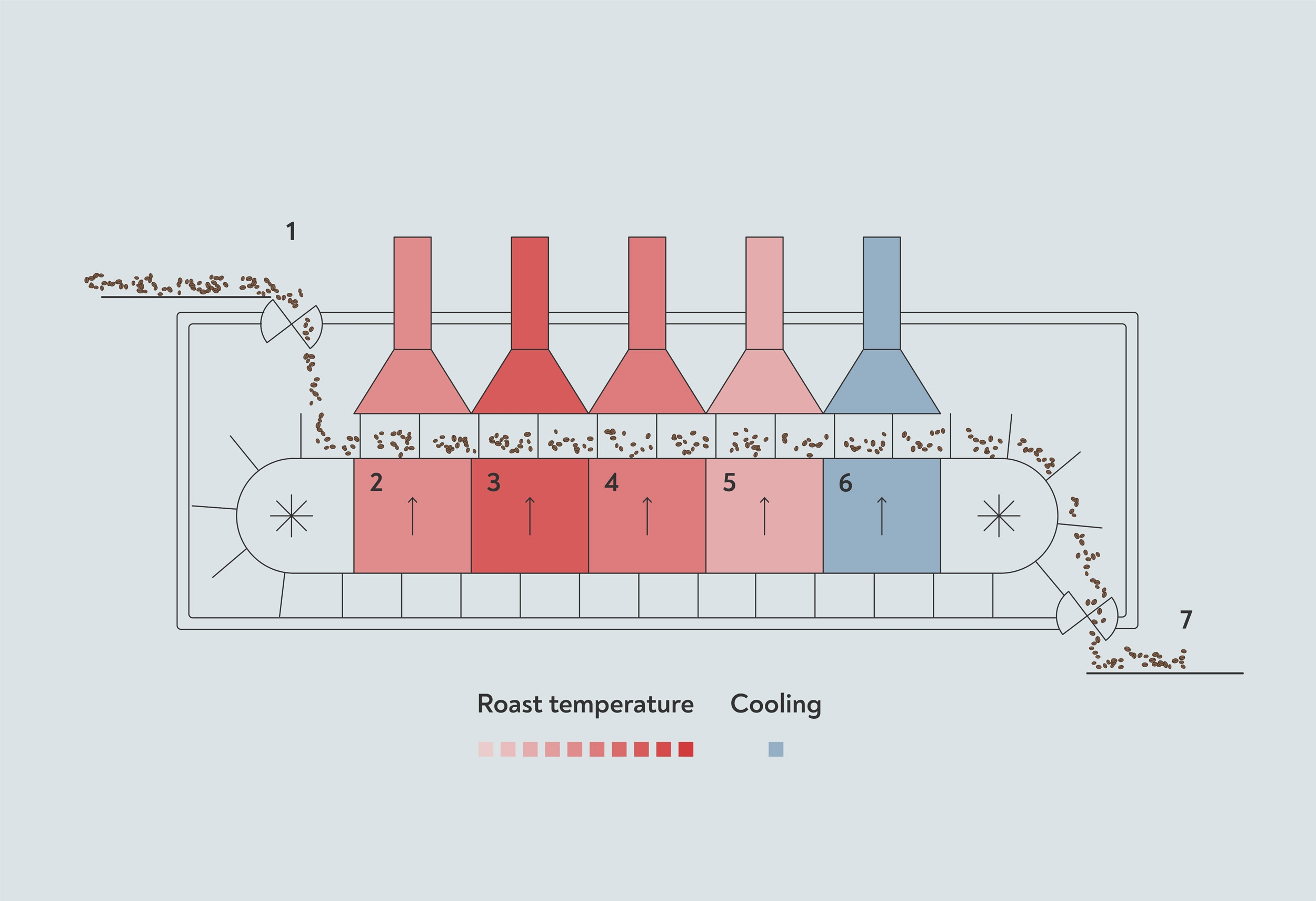

Other continuous roasters, such as the Nepro Vortex pictured below, use a conveyor belt to carry beans through the machine. Inside the roaster, different temperature zones along the bean’s route define the roast profile. The bed of beans is fluidised by the roasting or cooling gases in each zone.

Simplified diagram of a continuous roaster featuring different roasting zones to allow roast profiling. The hopper (1) continually feeds beans onto a conveyor belt. The beans pass through four different roasting zones (2–5) which are fluidised and heated by hot air at different temperatures. The beans then pass into a cooling zone (6), equipped with a spray of water to quickly stop the roast. Finally, the roasted, cooled beans are discharged from the machine (7).

Simplified diagram of a continuous roaster featuring different roasting zones to allow roast profiling. The hopper (1) continually feeds beans onto a conveyor belt. The beans pass through four different roasting zones (2–5) which are fluidised and heated by hot air at different temperatures. The beans then pass into a cooling zone (6), equipped with a spray of water to quickly stop the roast. Finally, the roasted, cooled beans are discharged from the machine (7).