In an indirectly heated drum roaster, the heat source is distanced from the drum itself. Heat is transferred to the beans primarily by convection — from hot air passing from the heat source into the drum. This type of design first became possible at the end of the nineteenth century, after Carl Salomon realised the importance of airflow in coffee roasting.

In his book All About Coffee, William Ukers (1922) credits the first indirectly heated roasting machine to Joseph Lambert — who is perhaps better known as the possible inventor of peanut butter (Smith 2007). Published patents from Lambert’s company describe roasting machines that feature a gas burner inside the drum, a common design at the time. It’s possible that the ‘indirect’ heating Ukers mentions in his book refers to the various methods Lambert’s company used to shield the beans from the direct heat of the flames in the machine.

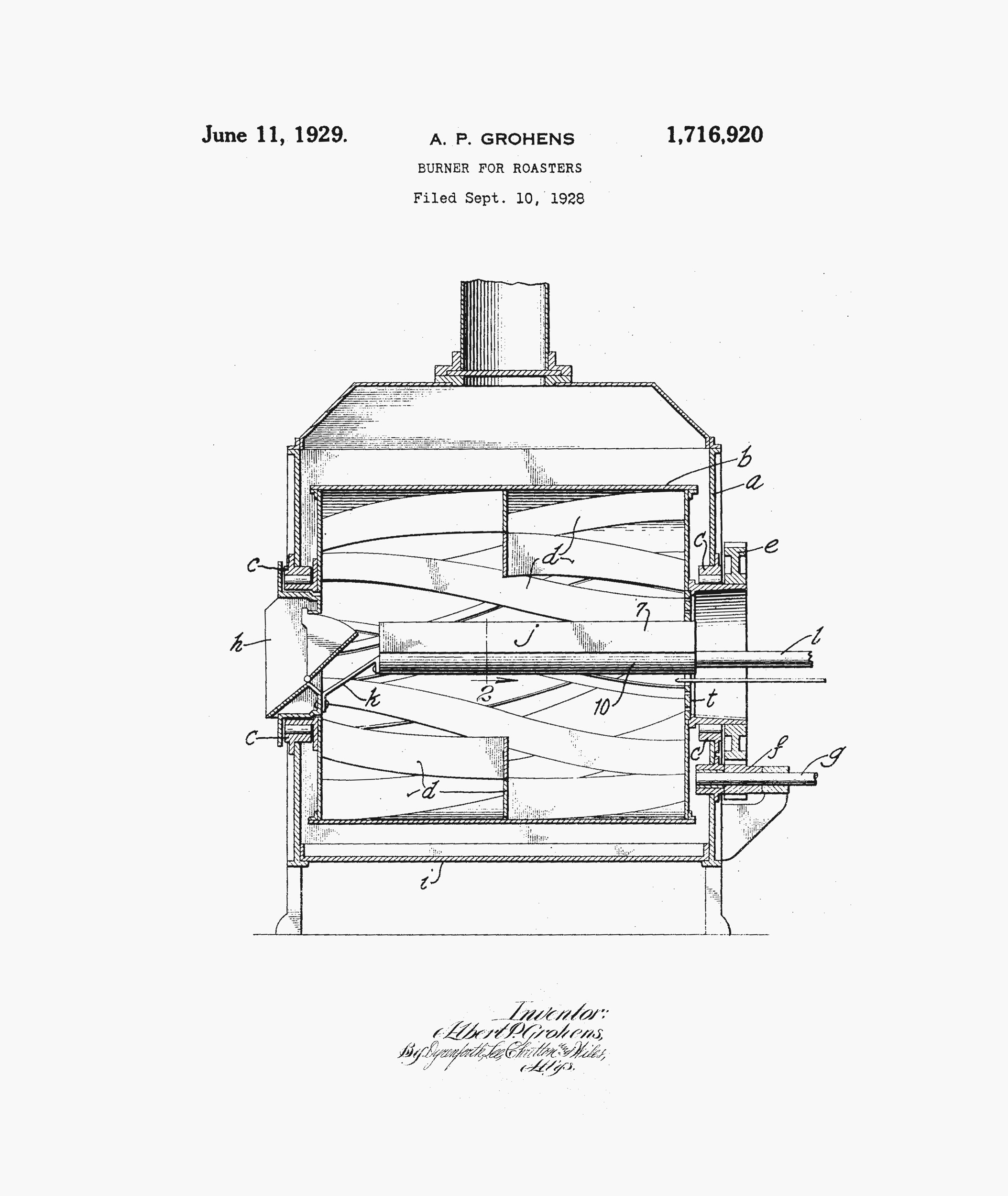

A Lambert Machine Company design for a roasting machine, featuring a gas burner (j) projecting into the middle of the drum. Source: Grohens 1928

A Lambert Machine Company design for a roasting machine, featuring a gas burner (j) projecting into the middle of the drum. Source: Grohens 1928

Regardless of who the true inventor was, indirectly heated roasting machines began to appear in the early twentieth century. A 1908 patent describes an indirectly heated design that uses a heat exchanger to heat air as it passes through the machine (Vogeler 1908). Keeping the burner separate from the roasting chamber means that no combustion gases enter the drum; only clean air or ‘a chemically inert gas’ (of a type not specified in their patent) is used to heat the beans.

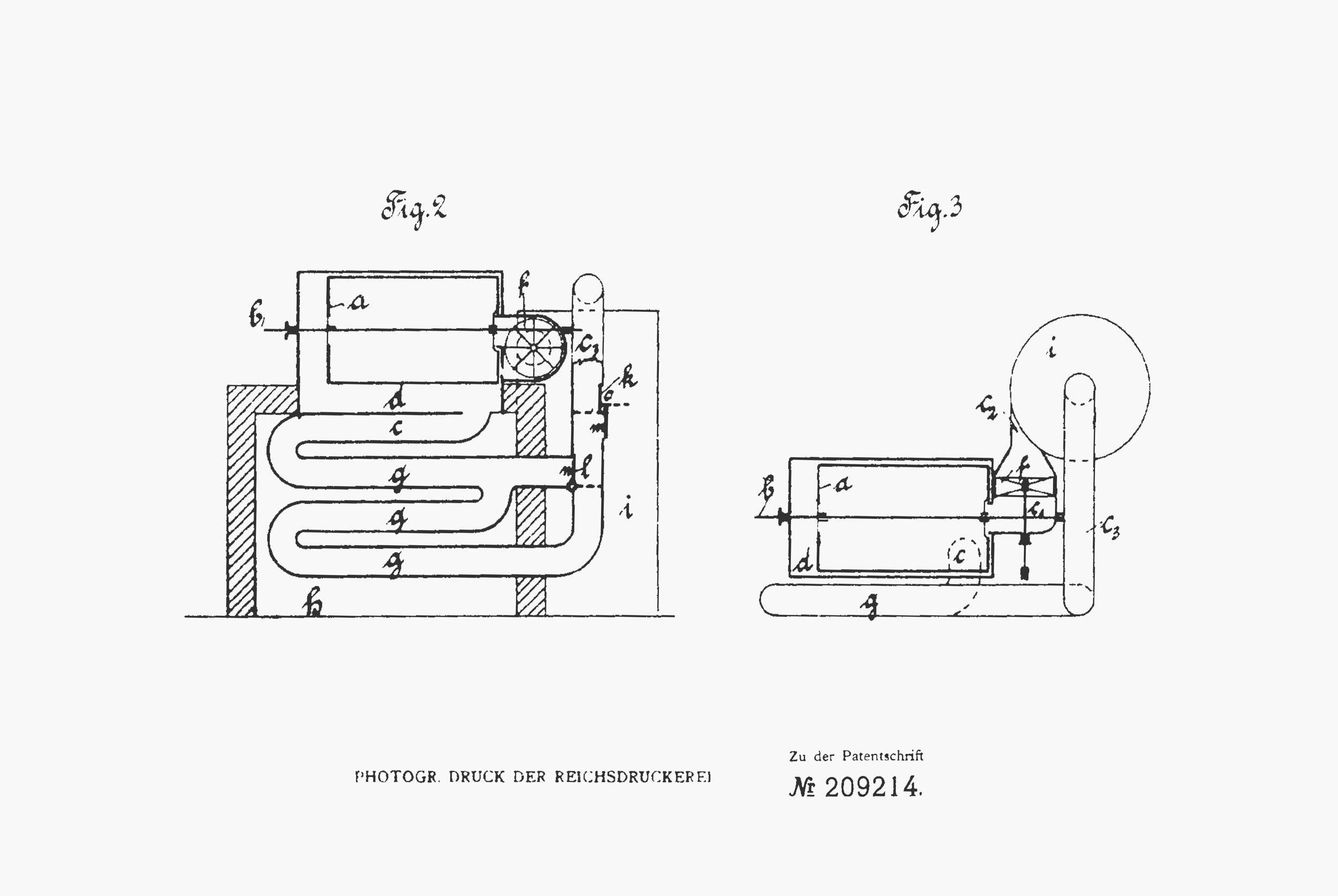

Theodor Vogeler’s 1908 design for an indirectly heated drum roaster uses a heat exchanger (g) to heat the air before it enters the drum (a).

Theodor Vogeler’s 1908 design for an indirectly heated drum roaster uses a heat exchanger (g) to heat the air before it enters the drum (a).

The first commercially successful indirectly heated drum roaster was Jabez Burns’s Thermalo machine, introduced in 1934 (Davids 2013).