The directly heated drum roaster consists of a rotating metal cylinder (the drum), closed at each end, placed over a heat source such as a flame. In directly heated roasting machines, the heat source heats the drum directly, which in turn heats the beans and the air inside the machine. In modern directly heated designs, some indirect heat is also applied by drawing hot air through the drum.

The term ‘directly fired’ is sometimes used to denote coffee roasting machines in which the beans have direct contact with the flames, via a perforated drum, particularly in the context of wood-fired roasting machines. This type of design operates differently to directly heated drums and is now a rarity.

الخلفية التاريخية

The directly heated drum roaster, as we know it today, evolved from cylindrical devices designed for roasting coffee at home that first came into use in the seventeenth century. Metal cylinders were filled with coffee, set over a fire, and turned by hand. When the roast was complete, the cylinder had to be removed from the fire, or the fire extinguished, before the coffee could be taken out. The cylinder was commonly sealed at both ends, and beans were introduced and removed via a hatch on the cylinder’s side wall.

ال domestic coffee roasting device, showing the hatch on the drum wall used to add or remove beans

ال domestic coffee roasting device, showing the hatch on the drum wall used to add or remove beans

The drums were made of solid or perforated metal. Perforated metal allowed closer contact with the flames and hence faster roasting, but perforated drums were gradually displaced by solid metal drums, which protected the beans from smoke and soot. Roasting times of around an hour were typical (Bersten 1993). Spherical drums were developed in the mid-nineteenth century; the first commercially successful spherical roaster was built in 1870 by Emmericher Maschinenfabrik und Eisengießerei (later renamed Probat).

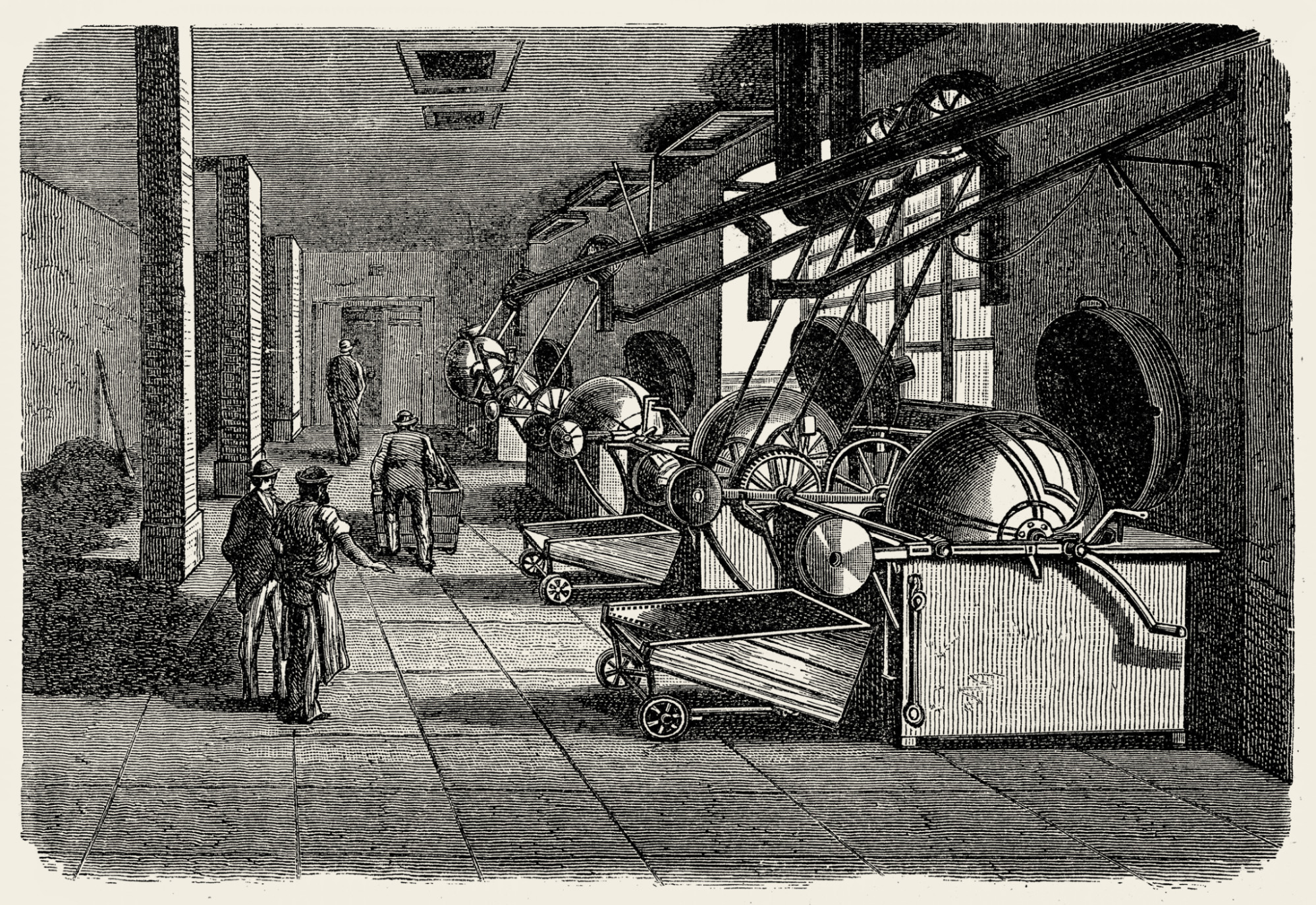

Nineteenth-century coffee-roasting machines featuring spherical drums

Nineteenth-century coffee-roasting machines featuring spherical drums

The need to remove the entire drum from the flame was a major impediment to the development of large commercial roasters.