A fluid-bed roaster uses airflow to partially or completely ‘fluidise’ the beans — lifting them up in the stream of air so that they move like a liquid. The beans freely circulate in the air and thereby roast evenly, without the need for moving paddles or a rotating drum.

A fluidised bed is made of solid particles (in this case, beans) suspended in an upwards flow of fluid (in this case, roasting gases). The upwards flow of air creates drag (friction) against the beans, which increases with the speed of the airflow. When the airflow is high enough that the drag force becomes equal to the weight of the beans, the whole bed becomes fluidised (RG Holdich 2002).

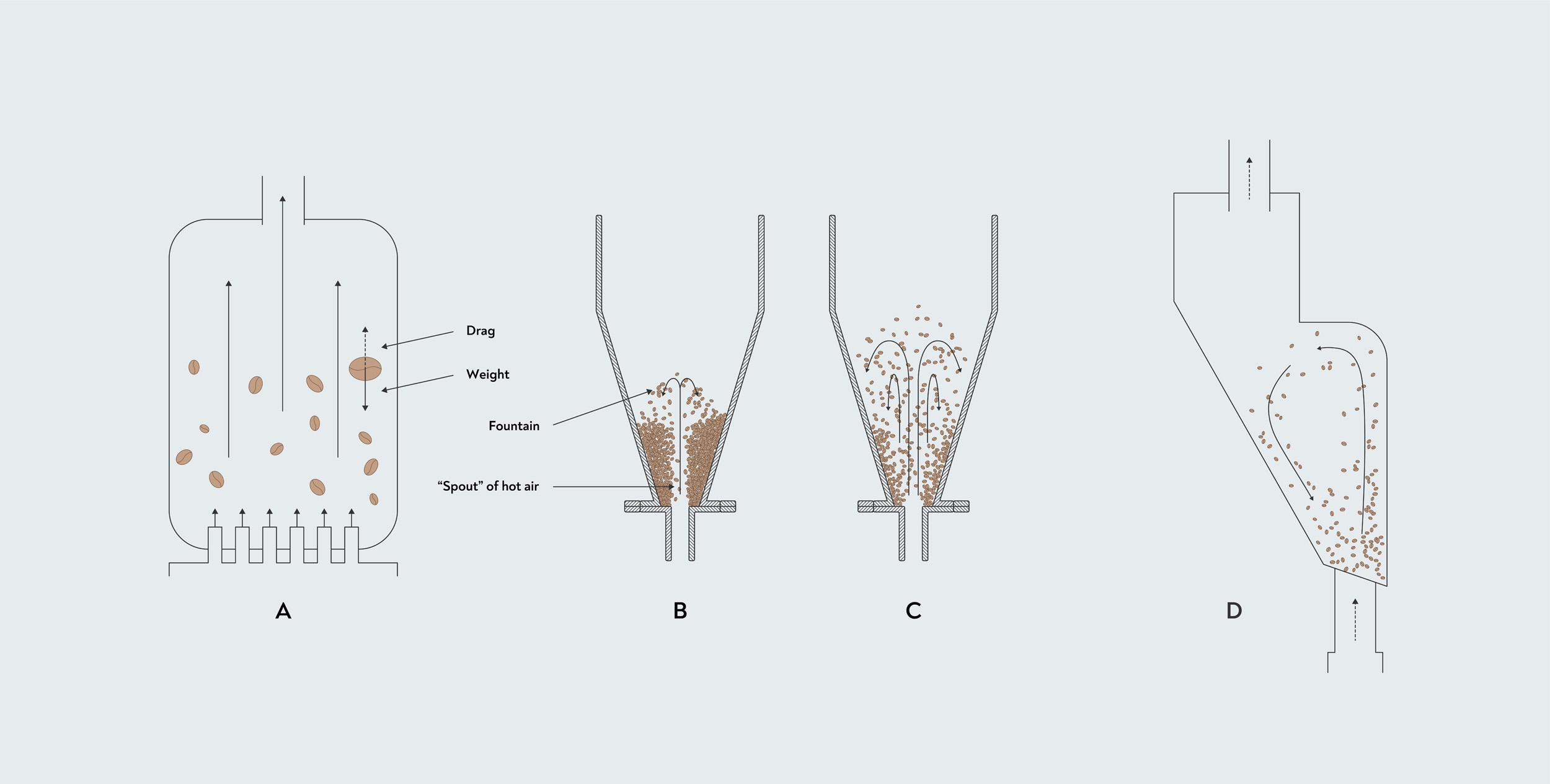

Because fluid-bed roasters are ‘single-pass’ and air is not recirculated, they can be energy intensive to run and generally require a lot more gas than a typical drum roaster. The air-to-bean ratio in a fluidised bed ranges from 7.3:1 to 12.8:1, while in ‘once-through’ drum roasters it is around 3:1 (Clarke 1987). In other words, you have to heat a lot more air to roast a batch in a fluid-bed roaster. Coffee beans are hard to fluidise and a spouted bed promotes better mixing of the beans and so, strictly speaking, most modern ‘fluid-bed’ roasters are actually spouted beds (see B and C in the figure below), wherein only part of the bed is fluidised (Schwartzberg 2002). Spouting requires less gas than fully fluidising the bed and transfers heat to the beans more efficiently (Eggers and Pietsch 2001).

The above diagram shows how fluid-bed and spouted-bed roasters work. In a fluidised bed (A), the friction of the air flowing past the beans creates an upwards drag force. When this force is equal to the downwards force from the weight of the beans, the bed becomes fluidised. In a spouted bed (B), only the part of the bed around the spout is fully fluidised, forming a ‘fountain’.

The above diagram shows how fluid-bed and spouted-bed roasters work. In a fluidised bed (A), the friction of the air flowing past the beans creates an upwards drag force. When this force is equal to the downwards force from the weight of the beans, the bed becomes fluidised. In a spouted bed (B), only the part of the bed around the spout is fully fluidised, forming a ‘fountain’.