As soon as the roast is finished, the beans must be cooled rapidly to end the roasting process and prevent loss of flavour. For optimal flavour, the temperature of the beans should drop to less than 40°C (104°F) in less than 4 minutes. If cooling takes longer, the coffee begins to lose sweetness and aroma, and might develop a ‘baked’ flavour.

Cooling roasted beans the old-fashioned way in a factory in Indonesia

Cooling roasted beans the old-fashioned way in a factory in Indonesia

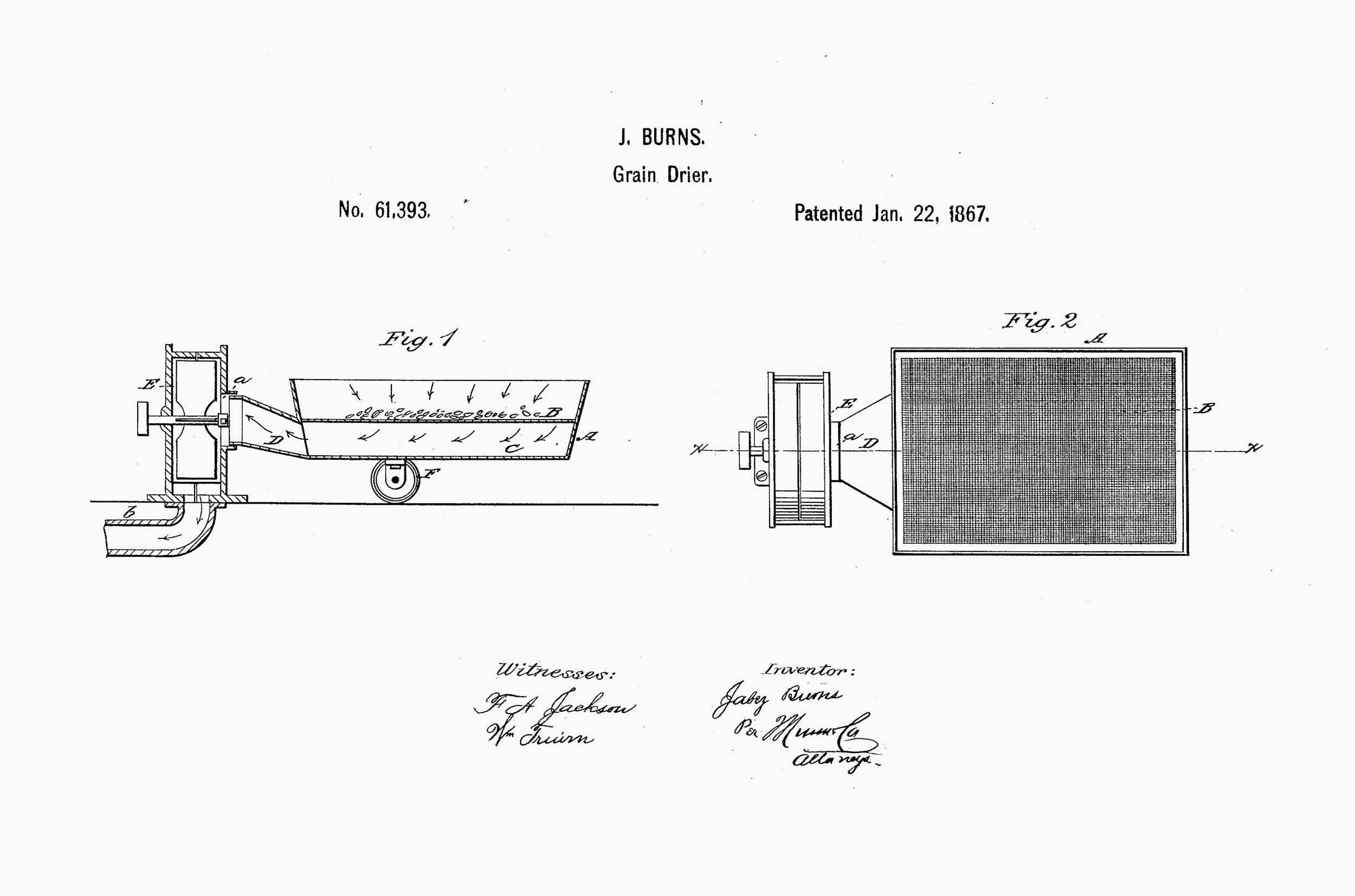

In early commercial roasters, workers poured the beans into large trays to cool after roasting, stirring them by hand. Jabez Burns designed the forerunner of the modern cooling tray, described in his 1867 patent. In Burns’s design, a fan sucked air downwards through a perforated bed. This method cooled the beans quickly and had the additional benefit of removing chaff and smoke — airborne elements that, according to Burns, were ‘inconvenient’ for the workers and increased the risk of fire. Burns also suggested passing the smoke into a furnace to burn any remaining particle residues — much like the function of a modern afterburner.

The forerunner of the modern cooling tray, from Jabez Burns’s 1867 patent

The forerunner of the modern cooling tray, from Jabez Burns’s 1867 patent

Cooling the beans terminates the chemical reactions that occur during roasting. If the beans cool too slowly, the continuing chemical reactions in the hot beans can give rise to a ‘baked’ flavour. Even with the use of powerful, modern cooling fans, chemical reactions in the beans can continue for up to 15 seconds after the end of the roast (Baggenstoss 2008).

The volatile compounds that give coffee its aroma are prone to evaporate more quickly at high temperatures. De Monte et al (2003) suggest that cooling reduces the pressure inside the beans and closes pores in the bean structure, further helping to retain aroma compounds in the bean.

Achieving sufficiently rapid cooling requires about 4 cubic metres of air for every kilogram of coffee (Ledezma et al 2017).