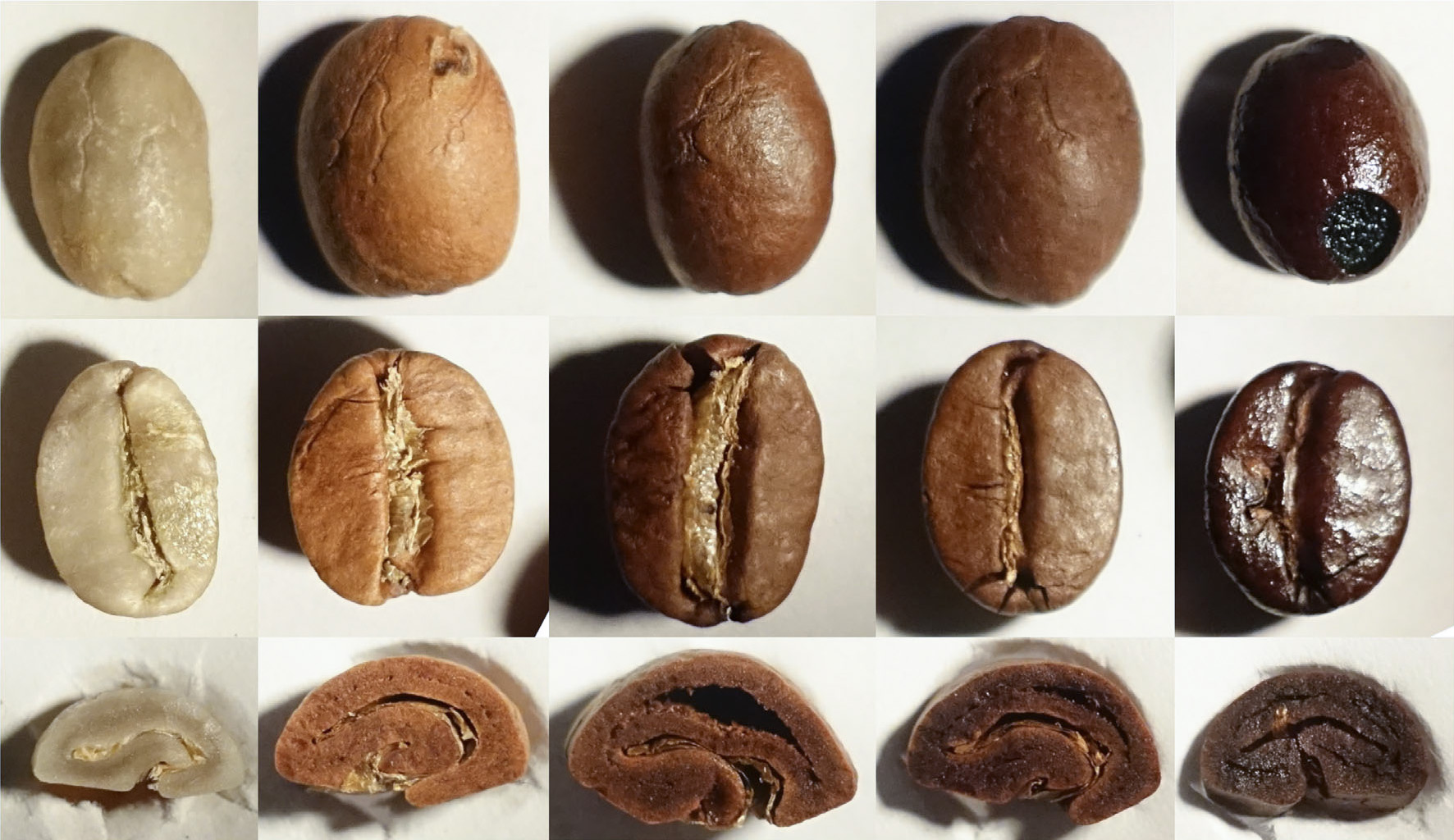

During roasting, pressure builds up in the beans as a result of the steam and carbon dioxide gas created during roasting. This pressure forces the beans to as much as double their original volume. The structure of the beans becomes more porous, and the beans become weaker and more brittle. These changes are key to making it possible to grind and extract the coffee (Pittia et al 2001).

Changes in bean structure during roasting. As roasting progresses, beans become larger and more porous. The stages of roast shown are, from left to right: green; beginning of first crack; end of first crack; start of second crack; end of second crack. Source: Yergenson and Aston 2019

Changes in bean structure during roasting. As roasting progresses, beans become larger and more porous. The stages of roast shown are, from left to right: green; beginning of first crack; end of first crack; start of second crack; end of second crack. Source: Yergenson and Aston 2019

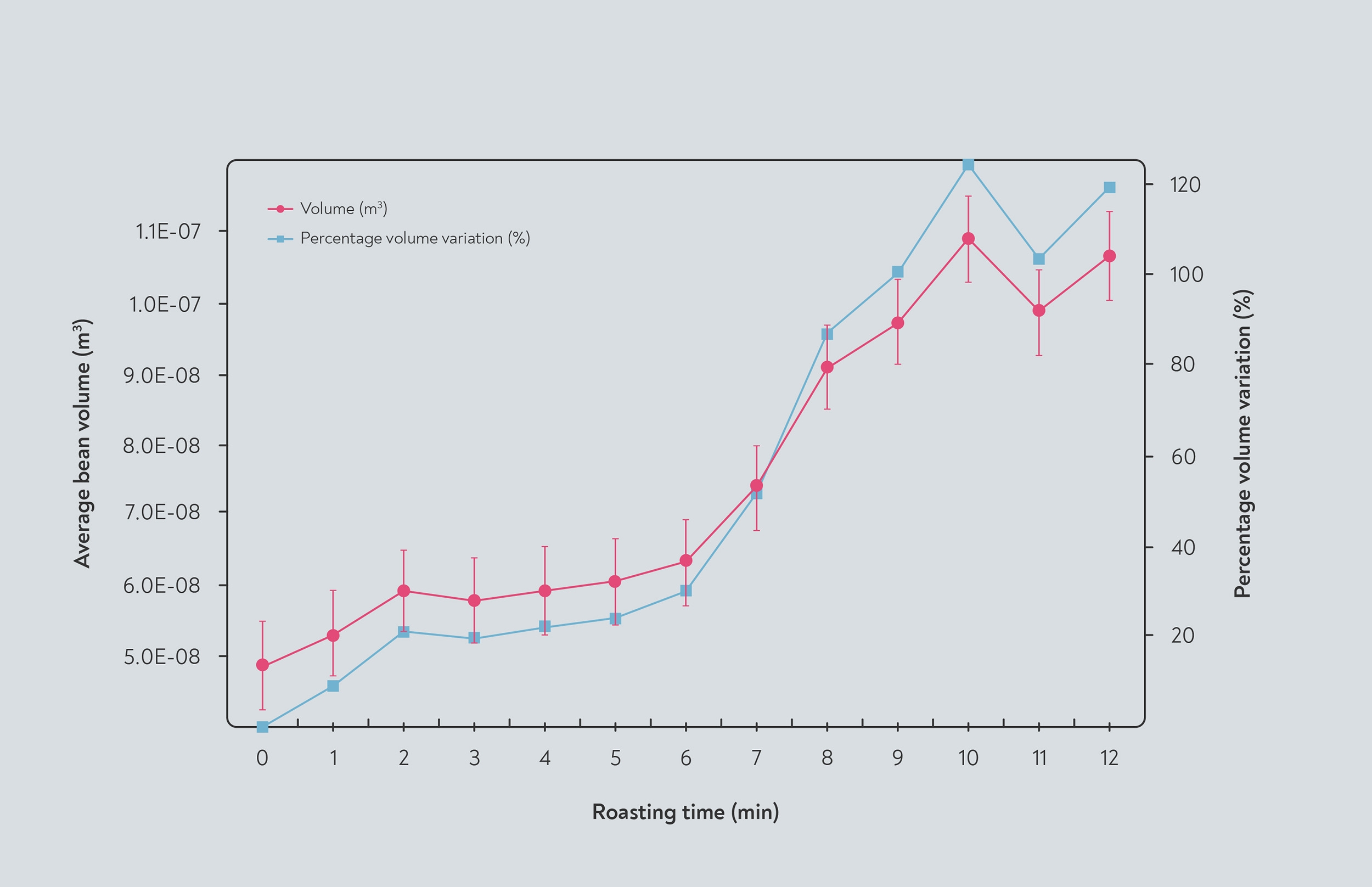

The beans don’t increase in size suddenly, the way popcorn does — rather, they swell continually throughout the roast (Bonnländer et al 2005). The size of the beans increases more quickly towards the end of the roasting process, however, when more carbon dioxide is being produced (Dutra et al 2001). The changes in size and porosity are closely linked to the amount and rate of carbon dioxide formation in the roast (Wang and Lim 2015).

Bean volume increases fastest towards the end of the roasting time. According to the study’s authors, the roast reached its optimum colour in 9 minutes. Adapted from Dutra et al (2001)

Bean volume increases fastest towards the end of the roasting time. According to the study’s authors, the roast reached its optimum colour in 9 minutes. Adapted from Dutra et al (2001)

Coffees roasted at higher temperatures or to a darker colour swell more and become more porous during roasting (Schenker et al 2008), presumably because of the greater amount of carbon dioxide released.

The pores in the bean vary in size, ranging from the large cavities created by the bean cracking open, down to nano-scale pores in the bean structure itself. Many of the pores in the bean structure are formed from the remnants of the cell walls,